In the rapidly evolving world of electronics, the flexible printed circuit (FPC) stands out as a game-changer. FPC technology offers endless possibilities for innovation. Its ability to bend and fit into compact spaces makes it ideal for modern devices. We see FPC prominently in smartphones, wearables, and medical devices. These circuits help create lighter and more efficient products.

Emerging technologies continue to redefine how we use flexible printed circuits. For instance, flexible screens and sensors are on the rise. They transform traditional designs, enhancing usability and performance. However, the journey is not without challenges. Manufacturers must address durability and performance issues. As industries adapt, they must consider the environmental impact of production.

Exploring the best uses of flexible printed circuits in 2026 reveals exciting developments. New materials and integration techniques may lead to breakthroughs in various fields. This evolution invites professionals to think creatively about applications. The future may hold unexpected innovations that challenge our current understanding.

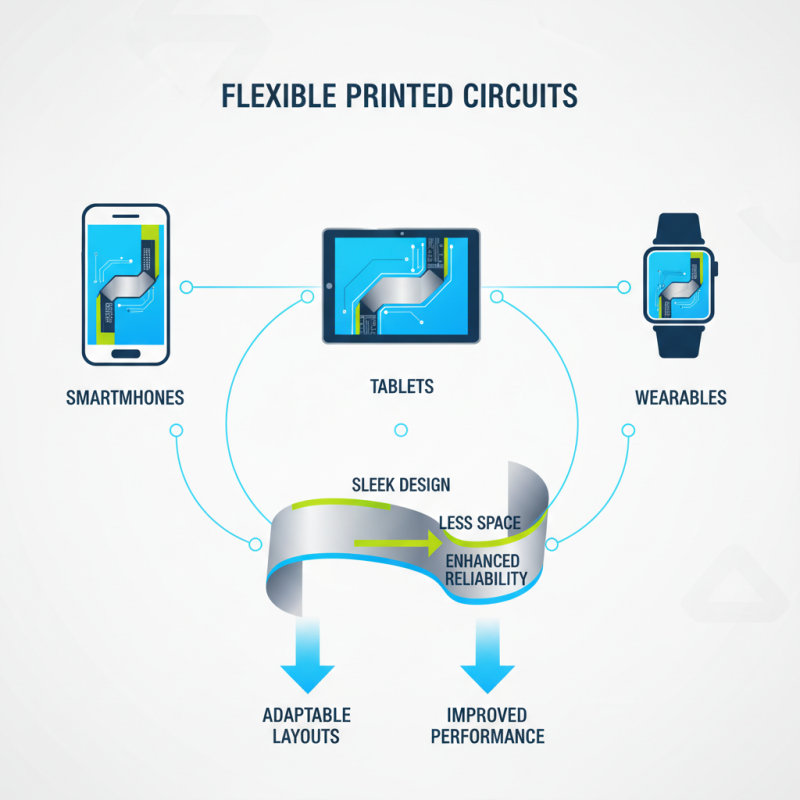

Flexible printed circuits (FPCs) are integral to modern consumer electronics. They enable sleek designs and reduce weight and space. Smartphones, tablets, and wearable devices all benefit from these circuits. Their adaptability allows for intricate layouts that are impossible with traditional wiring. This innovation facilitates better performance and reliability.

Tips: Consider how FPCs impact device longevity. Their ability to withstand flexing and bending is crucial. However, not all materials are created equal. Some might not endure the test of time.

As more devices strive for compactness, FPCs are increasingly essential. From the tiniest earbuds to larger display screens, they are everywhere. This versatility opens up new possibilities for integration. Yet, incorporating FPCs presents challenges. Manufacturers must balance cost against performance. Not every design will succeed; some will require reevaluation and adjustment.

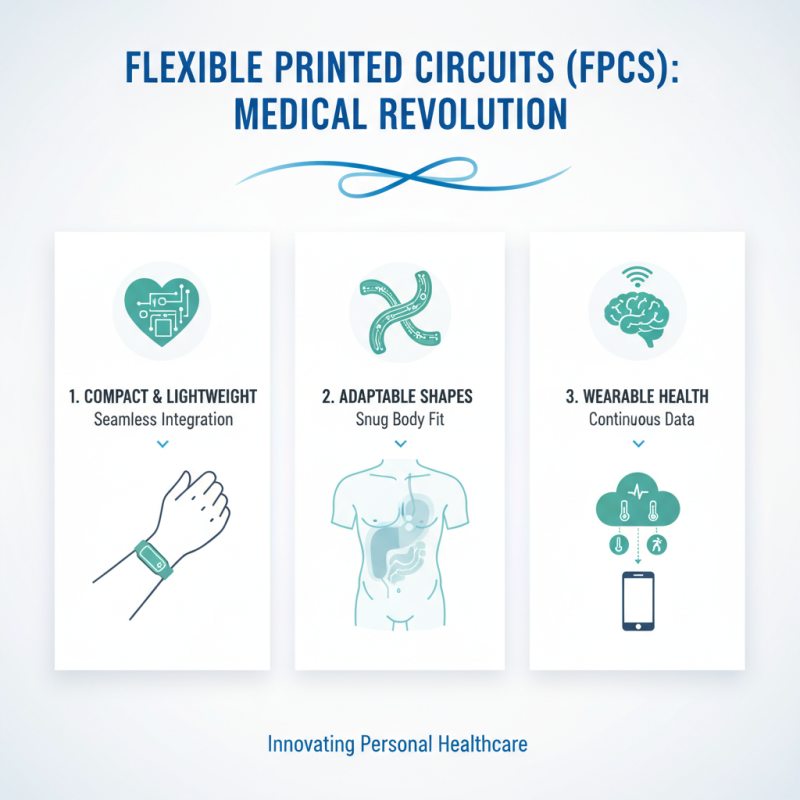

Flexible printed circuits (FPCs) are transforming medical devices. These circuits are lightweight and can be integrated into compact designs. Their flexibility allows for innovative shapes that fit snugly inside the human body. Consider wearable health monitors. They collect vital data without bulk. This seamless integration has opened new doors in personal healthcare.

FPCs are also key in surgical instruments. Their design allows for intricate movements during delicate procedures. This enhances precision while minimizing patient trauma. However, challenges remain. The durability of these circuits can be a concern. They must withstand harsh environments and regular use. It is crucial to find materials that address these issues.

Additionally, FPCs pave the way for telemedicine. Remote monitoring becomes easier with flexible electronics. Patients can have devices that adapt to their bodies. They are less obtrusive and more comfortable. Still, the technology is evolving. Not all designs strike the right balance between flexibility and functionality. Continuous improvement is essential to meet the growing demands.

Flexible printed circuits (FPCs) play a crucial role in automotive technology innovation. Their lightweight and thin profile significantly save space without compromising performance. These circuits enable complex connectivity in modern vehicles, facilitating advanced functions like infotainment systems and driver assistance features.

In electric vehicles, FPCs are vital for efficient power management. They help in connecting battery management systems and monitoring devices. However, the transition to FPCs isn't without challenges. Designers often face issues like durability and thermal management in harsh automotive environments. Ensuring the reliability of these circuits requires continuous testing and innovation.

Moreover, as vehicles become more autonomous, the demand for flexible circuits will rise. They will support communication between sensors and control units. Yet, integrating these technologies still poses hurdles, such as alignment and scalability. The industry must collaborate and innovate to overcome these obstacles and fully unlock the potential of flexible printed circuits in automotive applications.

The field of flexible printed circuits (FPCs) is evolving rapidly. With innovations in materials and manufacturing techniques, FPCs are becoming integral in various applications. Emerging trends highlight the use of new polymers and advanced manufacturing methods, enhancing performance and flexibility. Industries like healthcare, automotive, and consumer electronics are leading these advancements.

New materials, including high-temperature resistance polymers, are gaining traction. These materials can withstand harsher conditions while maintaining flexibility. Additionally, additive manufacturing is being explored for FPCs. This method allows for more intricate designs, which traditional methods struggle to achieve. Using additives can improve the durability and efficiency of circuits.

Tip: When considering materials, think about the specific environment where FPCs will be used.

Sustainability is also a growing concern in FPC manufacturing. Biodegradable materials are being highlighted for easier disposal. However, achieving perfect durability in these materials remains a challenge. There is still work to be done in balancing performance with eco-friendliness.

Tip: Test prototypes thoroughly. Different temperatures or environments can expose weaknesses in the circuits.

The landscape of FPCs is shifting. Innovations show promise, but not all advancements are flawless. Continuous improvement is vital for creating robust and efficient flexible printed circuits.

Flexible printed circuits (FPCs) are transforming industries. Their lightweight and compact design allows for intricate layouts. In portable electronics, they're essential for space saving. This innovation has made devices thinner and more efficient. However, challenges remain. Producing high-quality FPCs consistently is difficult. Variations in materials and thickness can lead to failures.

New uses for FPCs are emerging regularly. Medical devices are one significant area seeing growth. Wearable technology relies heavily on flexible circuits. They enable continuous health monitoring, which is crucial for patient care. Yet, the durability of these circuits must be questioned. They must withstand daily wear and tear without failing.

Sustainability is another challenge in this field. The production of flexible circuits often involves harmful materials. Developing eco-friendly alternatives is essential but challenging. Moreover, recycling options for used circuits are limited. Innovation needs to balance functionality with environmental responsibility. There is much to improve, and the conversation continues.