In the rapidly evolving world of electronics manufacturing, achieving high quality and efficiency in PCB assembly is paramount. As the backbone of almost every electronic device, printed circuit boards (PCBs) must be assembled with precision to ensure optimal performance and reliability. This guide presents the top ten PCB assembly tips that can significantly enhance the manufacturing process. By focusing on best practices, manufacturers can streamline operations while minimizing errors, ultimately leading to greater customer satisfaction.

From selecting the right materials to implementing effective quality control measures, understanding key strategies for PCB assembly is crucial. The insights provided will not only address common pitfalls but also highlight techniques that foster innovative solutions. By adopting these recommendations, manufacturers can not only improve production efficiency but also elevate the overall quality of their PCB assemblies. As we delve into these invaluable tips, let us explore how embracing these practices can transform your assembly processes and ensure success in the competitive electronics landscape.

When it comes to ensuring high-quality PCB assembly in electronics manufacturing, the selection of materials plays a crucial role. High-quality printed circuit boards (PCBs) start with the right substrate materials, which provide the foundation for durability and performance. Key factors to consider include the thermal properties, dielectric constant, and mechanical strength of the materials. Using materials that meet or exceed industry standards can help prevent failures and improve the overall reliability of electronic products.

In addition to the base materials, attention should be paid to other components such as copper foil and solder mask. The thickness and quality of the copper foil can significantly influence current handling and signal integrity. Furthermore, selecting a solder mask that offers appropriate adhesion and resistance to harsh environments will enhance the longevity of the PCB. By focusing on these aspects during the material selection process, manufacturers can ensure the production of PCBs that not only meet design specifications but also withstand real-world applications.

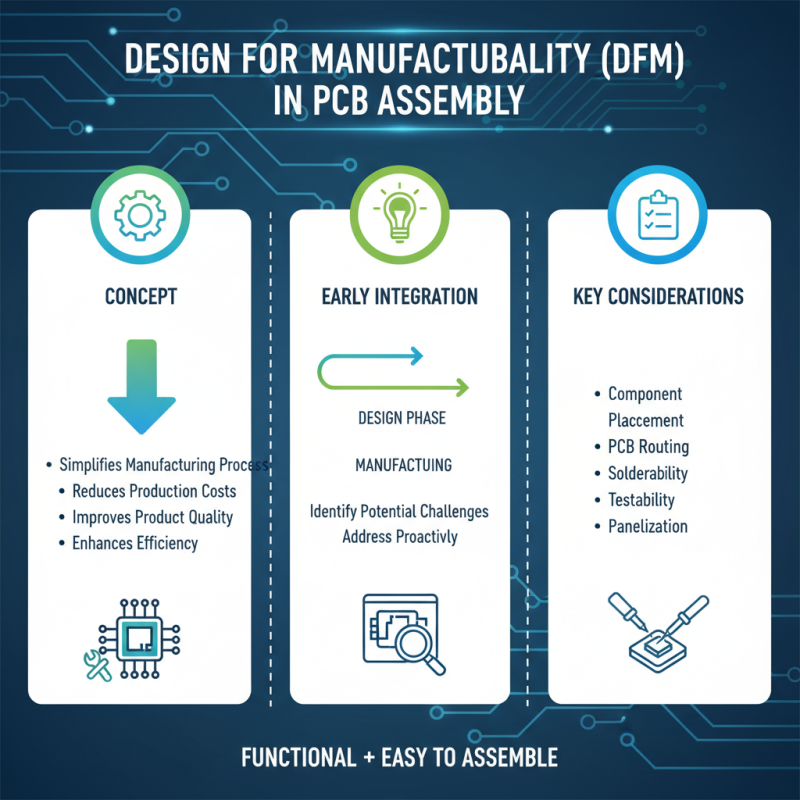

Design for Manufacturability (DFM) is a critical concept in PCB assembly that emphasizes the importance of designing circuit boards in a way that simplifies the manufacturing process. Effective DFM practices can significantly reduce production costs, improve product quality, and enhance overall efficiency. By integrating DFM principles early in the design phase, engineers can identify potential manufacturing challenges and address them proactively. This includes considerations such as component placement, routing, and solderability, ensuring that the final product is not only functional but also easy to assemble.

Another vital aspect of DFM involves selecting appropriate materials and components that align with manufacturing capabilities. By collaborating closely with manufacturers during the design phase, engineers can gain insights into the limitations and advantages of different processes, such as surface mount technology or through-hole soldering. This collaboration fosters a shared understanding of design constraints and manufacturing capabilities, allowing for optimal design adjustments that can facilitate smoother production runs. Ultimately, prioritizing DFM in PCB assembly leads to more reliable electronics products while minimizing the risk of costly defects and delays in the manufacturing process.

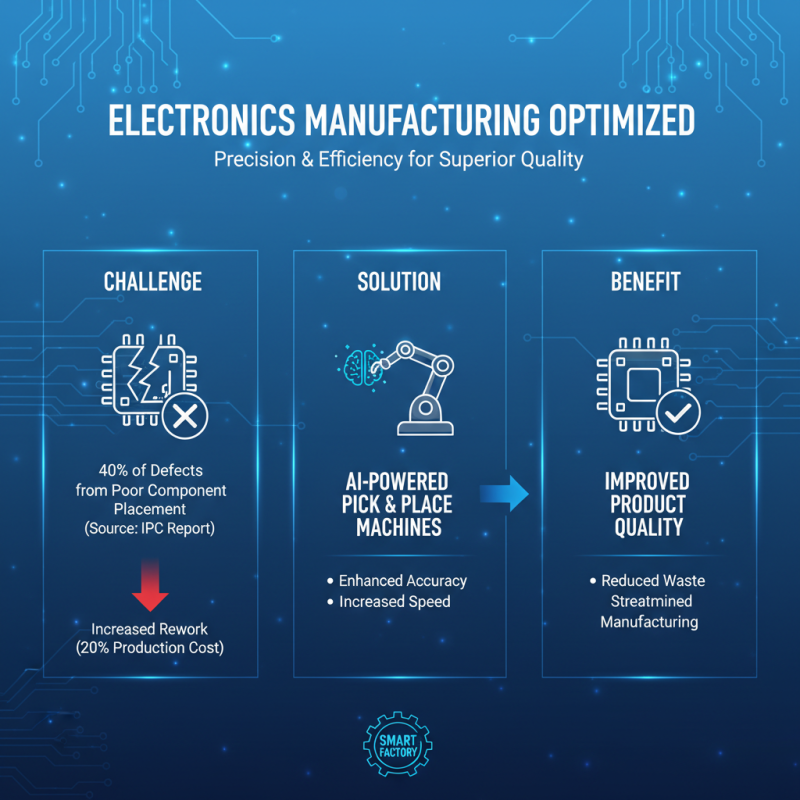

Optimizing component placement and soldering efficiency is crucial for enhancing the quality of electronic products while ensuring streamlined manufacturing processes. According to a report by IPC, the Association Connecting Electronics Industries, nearly 40% of defects in circuit boards are attributed to poor component placement. Achieving precision in this area can significantly reduce rework rates, which, as the same report highlights, can cost manufacturers up to 20% of the total production value. Utilizing advanced placement technologies, such as pick-and-place machines with AI capabilities, can enhance accuracy and speed, ensuring components are placed correctly with minimal waste.

Soldering efficiency is equally important in PCB assembly. A study conducted by the SMTA (Surface Mount Technology Association) found that automated soldering processes decreased cycle times by up to 30% compared to manual soldering methods. Furthermore, optimizing solder paste application can lead to improved joint reliability, which is critical for long-term product performance. Implementing techniques such as laser soldering or using selective soldering systems can provide better control over the soldering environment, minimizing thermal load on sensitive components. These advancements not only enhance product quality but also drive down operational costs, creating a more efficient production line in the competitive landscape of electronics manufacturing.

Quality control is a critical aspect of PCB manufacturing, ensuring that the end products meet the required specifications and function reliably in their intended applications. Effective testing and inspection strategies are paramount for identifying defects early in the production process. One common method is automated optical inspection (AOI), which uses high-resolution cameras to detect soldering issues, component misalignment, and other defects that could compromise the integrity of the PCB. By integrating AOI into the manufacturing workflow, manufacturers can drastically reduce the likelihood of defective assemblies reaching the final stages of production.

Another vital strategy involves functional testing, where the assembled PCB is subjected to real-world operating conditions to verify its performance. This can include powering up the circuits and checking for electrical continuity, signal integrity, and thermal performance. Moreover, incorporating in-circuit testing (ICT) can further enhance quality assurance by pinpointing faults in individual components on the PCB. These inspection and testing techniques not only improve product quality but also enhance overall efficiency by minimizing waste and rework, ultimately leading to a more reliable end product that meets or exceeds customer expectations.

The integration of automation and artificial intelligence (AI) in PCB assembly processes is transforming the landscape of electronics manufacturing. According to a report by ResearchAndMarkets, the global PCB assembly market is projected to reach $86.49 billion by 2025, driven largely by technological advancements. Automation in PCB assembly not only significantly reduces the time required for components to be placed on a printed circuit board, but it also minimizes human error, enhancing overall product quality.

AI technologies are further pushing the boundaries of efficiency in PCB assembly. Through the implementation of machine learning algorithms, manufacturers can optimize their production lines in real time. Studies indicate that companies adopting AI-driven processes have seen a reduction in defect rates by up to 30%, while simultaneously increasing throughput. Additionally, predictive maintenance powered by AI analytics helps identify potential equipment failures before they occur, thereby reducing downtime and maintenance costs. As manufacturers continue to embrace these technologies, the synergy between automation and AI is expected to lead to greater operational efficiencies and higher-quality production in the evolving PCB assembly sector.

| Tip No. | Tip | Description | Impact on Efficiency |

|---|---|---|---|

| 1 | Optimized Layout | Design PCBs with minimal component distance. | Reduces assembly time and errors. |

| 2 | Automated Soldering | Use machines for consistent soldering. | Increases speed and reduces defects. |

| 3 | Quality Components | Select high-quality components. | Improves reliability and performance. |

| 4 | Regular Maintenance | Maintain assembly equipment regularly. | Prevents downtime and defects. |

| 5 | Employee Training | Train employees on best practices. | Enhances skills and reduces errors. |

| 6 | Environmental Control | Control humidity and temperature. | Minimizes component damage. |

| 7 | Prototype Testing | Test prototypes before bulk production. | Identifies issues early. |

| 8 | Use of Automation | Incorporate robotics in assembly. | Boosts production rates. |

| 9 | Data Analysis | Analyze production data. | Enhances decision-making. |

| 10 | Supplier Collaboration | Work closely with suppliers. | Improves material quality and delivery. |