In today's fast-paced electronics industry, choosing the right components is crucial. Rigid flex circuit boards have emerged as a popular choice due to their versatility and efficiency. According to industry reports, the rigid flex market is projected to grow significantly, with a CAGR of over 10% in the next five years. This growth is driven by the demand for compact and lightweight electronic devices.

When selecting rigid flex circuits, several factors need consideration. Board thickness, layer count, and material type can impact performance. Although these aspects may seem straightforward, they require careful evaluation. Many projects fail to account for thermal management issues, which are critical in high-performance applications. Complex designs often face challenges that need addressing early in the development process.

While rigid flex technology offers several advantages, it is not without its drawbacks. Sometimes, cost becomes a limiting factor, especially for budget-conscious projects. Moreover, the intricate nature of these boards can lead to manufacturing difficulties. A thorough understanding of your project's specific needs will ultimately guide you to make informed decisions, ensuring success in a competitive landscape.

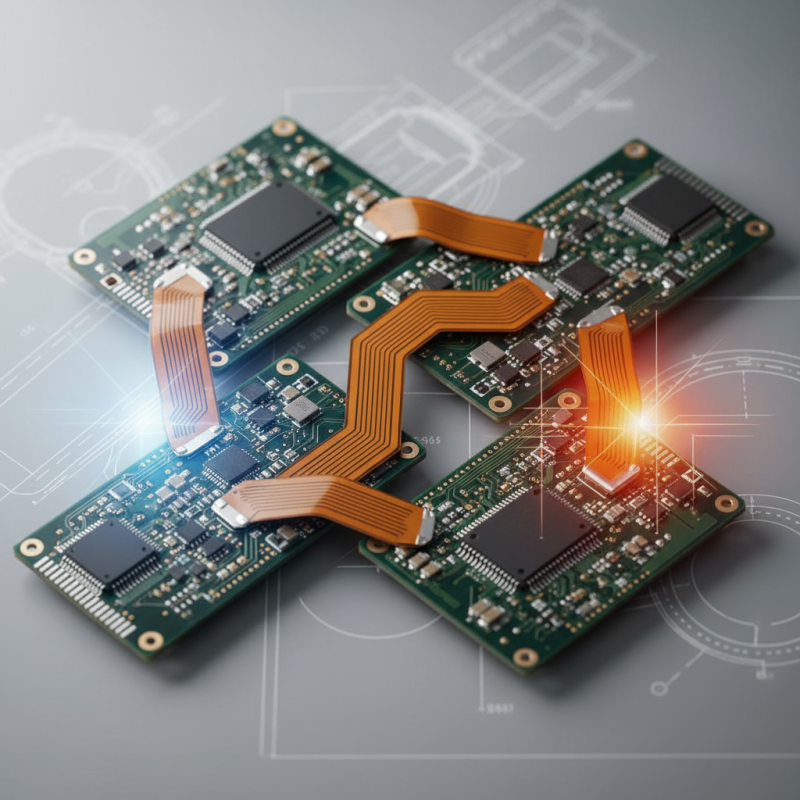

Rigid flex circuit boards combine the attributes of both rigid and flexible circuits. They feature rigid sections for mounting components and flexible areas for connecting to other elements. This combination allows for complex designs in limited spaces.

When selecting rigid flex circuits, pay attention to the substrate materials. Polyimide is common due to its excellent thermal stability. However, not all applications require the same material. Sometimes, a less durable option suffices.

**Tip:** Consider the environment where the board will be used. Factors like temperature and humidity can influence your choice.

Design complexity can lead to challenges. For example, intricate designs might be difficult to manufacture. Oversized pads and small traces can sometimes pose problems during production.

**Tip:** Simplicity often leads to a more successful board. Test your design with basic elements before adding complex features. Keep it straightforward.

Overall, understanding the basics of rigid flex circuit boards can lead to better choices for your projects. Think about the long-term performance. Acceptance of imperfection may drive better results.

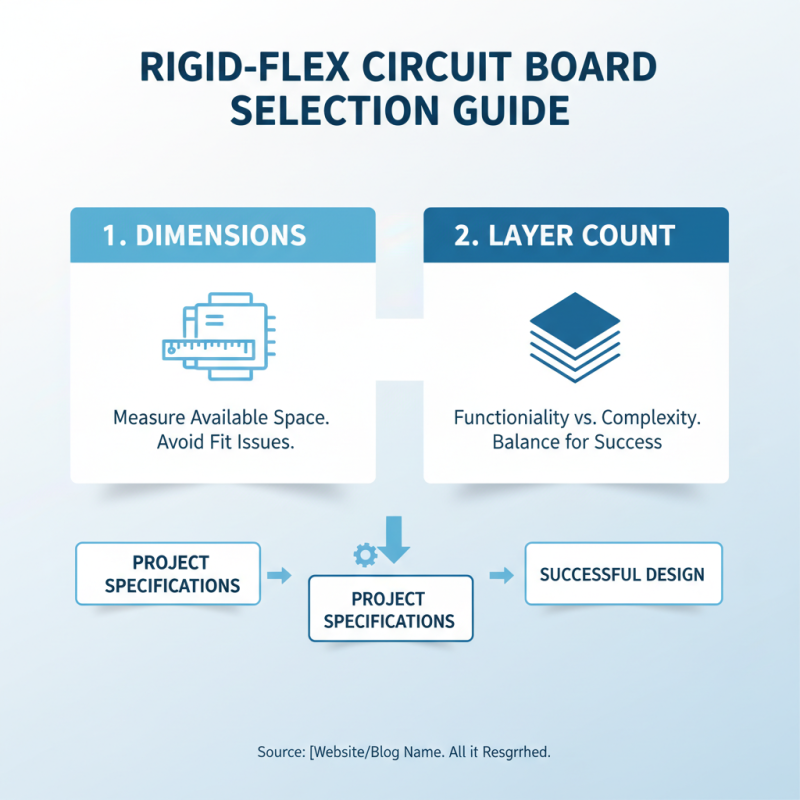

When selecting rigid flex circuit boards, understanding your project's specifications is critical. Start by considering the dimensions. Measure the space available in your device. A slight miscalculation can lead to fit issues. Then, assess the layer count. More layers can increase functionality but also complexity. Balancing these factors is essential for a successful design.

Another key specification is the material used. Different materials offer various benefits. Some are more flexible, while others provide better conductivity. Your choice impacts durability and performance. Pay attention to the temperature range as well. If your device generates heat, it needs materials that withstand high temperatures.

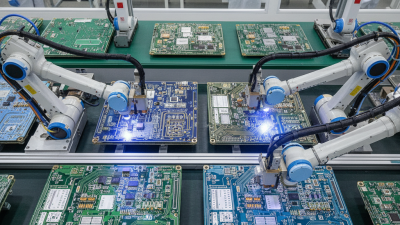

Don't forget to consider the manufacturing process. Complex designs may require special techniques. This can affect lead times and costs. Be prepared for potential revisions. Design iterations are part of the development journey. Take time to review and refine your requirements. Mistakes in this phase can lead to costly delays. Balancing all these elements is a challenge, but it's vital for a successful project.

When selecting rigid flex circuit boards, the material choices play a key role. The substrate is crucial. A common choice is polyimide, known for heat resistance and flexibility. Yet, it can be more expensive than alternatives. Some projects may opt for FR-4. It’s economical but lacks flexibility. This trade-off can impact performance.

The copper thickness also matters. Thicker copper can handle higher currents. This might be essential for power electronics. However, it can increase weight and cost. Balancing these factors is tricky. Some designers rush this decision. They find later that their boards overheat.

Consider surface finishes too. ENIG (Electroless Nickel Immersion Gold) offers durability. But the process can be lengthy and costly. Less durable finishes might save time and money. However, they could lead to failures. This decision often weighs on the project’s budget and expected lifespan. Reflecting on these details ensures better outcomes for your designs.

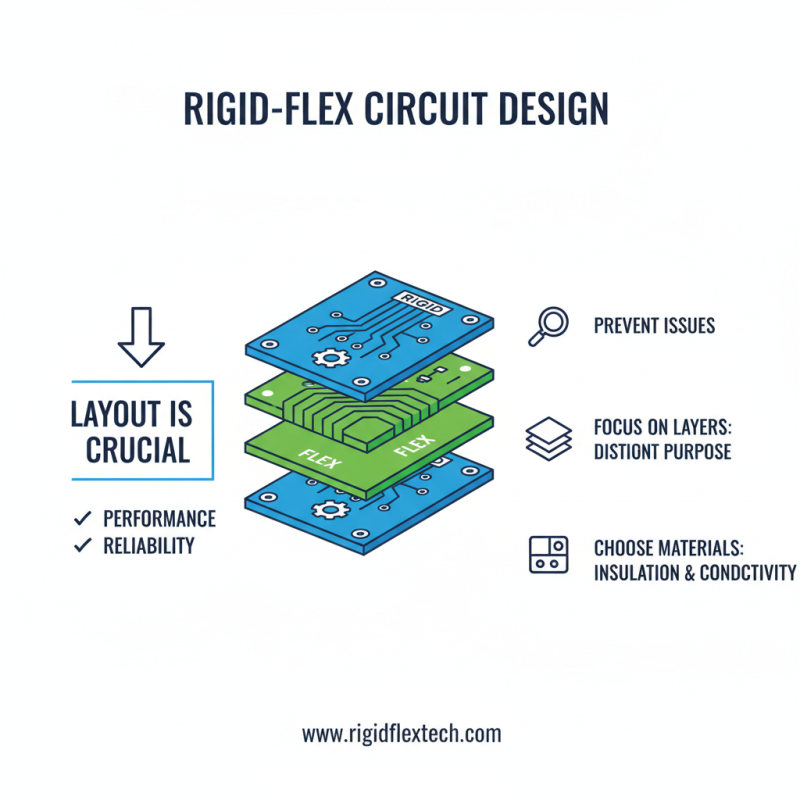

When designing rigid flex circuit boards, the layout is crucial. It directly impacts performance and reliability. Careful consideration of the design can prevent many issues. Start by focusing on the layers. Ensure each layer serves a distinct purpose. Use the right materials for insulation and conductivity.

Placement of components is vital. Keep high-frequency parts close together. This minimizes noise and improves efficiency. Routing traces can be tricky. Aim for shorter traces. Avoid sharp angles for smoother signal flow. These choices can make a noticeable difference.

Also, think about the bending areas. Rigid flex boards will flex, so avoid placing critical components in these zones. This can lead to unexpected failures. Testing your layout with simulations is a smart move. It highlights potential problems before physical production begins. It’s easy to overlook, but this step is essential for success.

When assessing cost-effectiveness in rigid flex circuit boards, it's vital to look beyond just the price. The overall value includes reliability, durability, and functionality. Consider the specific needs of your project. Will the board be exposed to heat, moisture, or stress? These factors can significantly impact your long-term costs.

Supplier options play a crucial role. Research various manufacturers. Look for those who have experience in your industry. A reputable supplier often provides better technical support. Don’t just focus on the cheapest option; consider their ability to meet deadlines and offer warranty protection. A cheaper board may lead to higher costs later due to failures or delays.

Evaluating potential suppliers can be tricky. Not all companies have the same focus on quality. Examine reviews and ask for samples. Some may fall short of expectations, despite low initial quotes. This can lead to frustration and project delays. Take time to reflect on your priorities and make informed decisions for optimal outcomes.