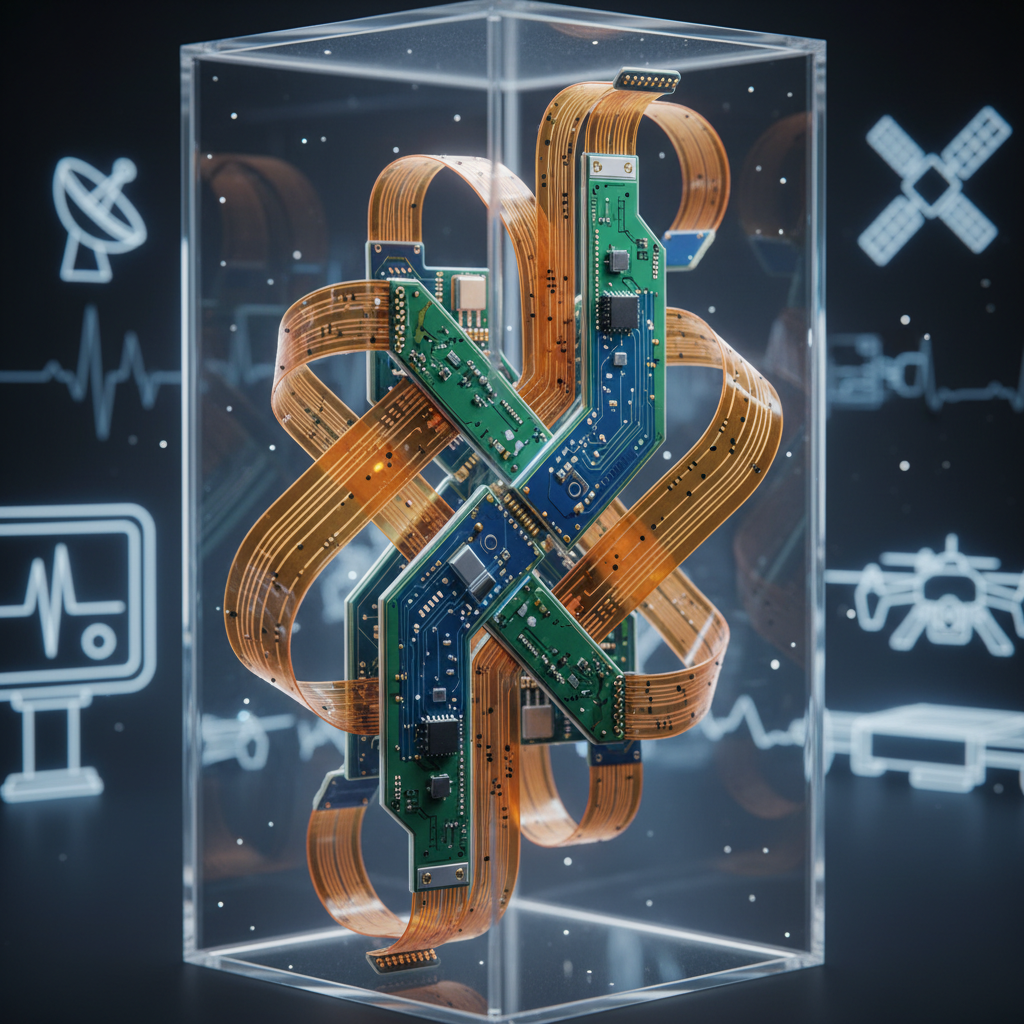

In today's rapidly evolving electronics landscape, the choice of circuit board technology can significantly influence the success of a project. Among various options, rigid flex PCBs have emerged as a popular solution, combining the advantages of both rigid and flexible circuit boards. According to a recent report published by ResearchAndMarkets, the global rigid flex PCB market is projected to grow at a CAGR of 10.5% from 2021 to 2026, highlighting the increasing reliance on this technology in sectors such as aerospace, automotive, and consumer electronics.

Expert insights shed light on this transformative trend. John Smith, a leading authority in PCB technology, emphasizes the importance of selecting the right rigid flex solution, stating, "Choosing the appropriate rigid flex PCB is critical for ensuring the performance and reliability of your device, especially in applications where space and weight are at a premium." This underscores the growing demand for sophisticated board designs that meet the rigorous requirements of modern electronics.

As engineers and designers navigate the complexities of rigid flex PCBs, understanding the key factors that influence their selection becomes paramount. In this article, we present the top 10 tips for choosing the right rigid flex PCB for your project, ensuring that you make an informed decision that aligns with both performance and budgetary considerations.

Rigid flex PCBs, combining the benefits of both rigid and flexible circuits, offer unique advantages for various applications. Their capability to withstand mechanical stress and save space is particularly beneficial in industries like aerospace, automotive, and consumer electronics. By integrating multiple functionalities into a single unit, they reduce the number of components needed, which can enhance performance and reliability.

When choosing a rigid flex PCB, consider the environmental conditions it will face. For instance, if the board will be exposed to high temperatures or humidity, opting for materials that can withstand these stresses is crucial. Also, ensure that the design incorporates proper flexural parameters to allow bending without compromising integrity.

Another important tip is to collaborate closely with your manufacturer early in the design process. They can provide insights on assembly techniques, lead times, and potential design optimizations that can save cost and enhance the functionality of your final product. By prioritizing these factors, you can ensure a successful integration of rigid flex PCBs into your projects.

| Tip # | Tip Description | Benefit | Considerations |

|---|---|---|---|

| 1 | Define Project Requirements | Helps in selecting appropriate specifications | Consider size, flexibility, and environment |

| 2 | Evaluate Material Options | Ensures durability and performance | Check thermal and electrical properties |

| 3 | Consider Layer Count | Affects complexity and design options | Higher layers can mean increased cost |

| 4 | Assess Manufacturing Capabilities | Ensures design can be produced | Not all manufacturers can handle rigid flex |

| 5 | Check Flexibility Requirements | Improves product ergonomics | Consider bending radius and fatigue |

| 6 | Evaluate Cost Factors | Helps in budgeting | Balance price with performance needs |

| 7 | Plan for Testing and Validation | Ensures reliability | Include environmental simulations |

| 8 | Consult with Design Engineers | Leverages technical expertise | Collaborate for optimal outcomes |

| 9 | Review Compliance and Regulations | Avoid legal issues | Stay updated on industry standards |

| 10 | Choose a Reliable Manufacturer | Enhances product quality | Check feedback and certifications |

When selecting the right rigid flex PCB for your project, it’s crucial to consider several key factors that can significantly impact both performance and longevity. With the rigid flex PCB market estimated to reach USD 77.7 billion by 2034, growing at a remarkable CAGR of 11.70%, it's evident that industries are increasingly relying on these components for their innovative designs.

One important aspect to evaluate is the design complexity. Rigid flex PCBs are versatile, accommodating intricate designs necessary for advanced applications in aerospace, defense, and medical markets where compactness and lightness are crucial.

Another important consideration is the material and layering of the PCB. The growing demand in sectors such as automotive, where the market is poised to hit USD 18.14 billion by 2034, is driven by the need for enhanced safety features and electrification. Selecting the appropriate materials can ensure durability and minimize signal loss, particularly important in high-frequency applications like 5G communications. Additionally, evaluating the manufacturing processes and reliability of the supplier is essential to ensure that the PCBs meet the stringent quality standards required for high-performance sectors.

When embarking on a rigid-flex PCB project, understanding the design requirements is paramount. Rigid-flex PCBs are increasingly favored for their ability to save space and enhance reliability, particularly in advanced applications such as medical devices and aerospace electronics. According to a recent study by MarketsandMarkets, the rigid-flex PCB market is projected to reach $7.27 billion by 2023, growing at a CAGR of 8.5%. This growth highlights the importance of selecting the right design parameters tailored to specific project needs.

Key considerations should include the number of layers, bending radius, and interconnectivity. Industry standards dictate that a typical bending radius for rigid-flex designs should be at least 5 times the thickness of the flex layers. Failure to adhere to these specifications can lead to mechanical failure. Additionally, engineers must evaluate thermal management as temperature extremes can significantly affect performance. IPC-2223 standards further guide designers on best practices in terms of material selection and layout to ensure a reliable final product. By addressing these design factors early in the project, engineers can optimize functionality and enhance the overall performance of their rigid-flex PCBs.

When selecting a rigid flex PCB for your project, understanding the manufacturer’s capabilities and expertise is crucial. This involves evaluating their production techniques, quality assurance processes, and technical support. A manufacturer with a proven track record should demonstrate a deep understanding of the specific requirements pertinent to your application. Look for certifications indicating compliance with industry standards, as these are often indicative of a manufacturer’s commitment to quality.

In addition, consider the manufacturer’s experience with similar projects. Engaging with manufacturers who have successfully produced rigid flex PCBs for your industry can provide valuable insights. Their expertise can not only help mitigate risks associated with design and production challenges but also enhance the overall reliability of your product. When possible, ask for references or case studies that showcase their past successes and partnerships, allowing you to evaluate their compatibility with your project’s needs.

This bar chart illustrates the evaluation criteria that are crucial for selecting the right rigid flex PCB manufacturer for your project. Each criterion is rated on a scale from 0 to 100, reflecting its importance in the decision-making process.

When considering rigid flex PCB solutions, budgeting is a crucial aspect that can significantly impact the success of your project. The global rigid flex PCB market is projected to grow at a compound annual growth rate (CAGR) of approximately 8% from 2023 to 2030, reflecting the increasing demand for advanced electronics in various sectors. Understanding the cost components – such as materials, labor, and fabrication processes – can help in formulating a realistic budget.

One essential tip for managing costs is to evaluate the materials used in the PCB. High-quality materials can enhance performance but come at a premium. For instance, the use of polyimide substrates may lead to better thermal performance compared to less expensive alternatives.

Additionally, consider the scale of production; manufacturing in larger volumes often results in reduced per-unit costs, which can be beneficial for your overall budget.

Another significant consideration is to look into the design complexity and its impact on costs. More intricate designs can increase fabrication expenses due to longer production times and greater material usage. Therefore, ensuring that your design is optimized for both functionality and manufacturability is key.

Engaging with a supplier who understands your budget constraints while engineering efficient designs can lead to significant savings.