As the world of electronics continues to evolve, so do the innovations within the rigid flex PCB (Printed Circuit Board) sector. In anticipation of 2025, experts predict that the landscape will be shaped by cutting-edge technologies and trends that will redefine the capabilities of rigid flex PCB applications. According to Dr. Emily Johnson, a leading expert in flexible electronics, “The integration of advanced materials and manufacturing techniques will unlock unprecedented potential for rigid flex PCBs, enhancing their performance and versatility in various applications.”

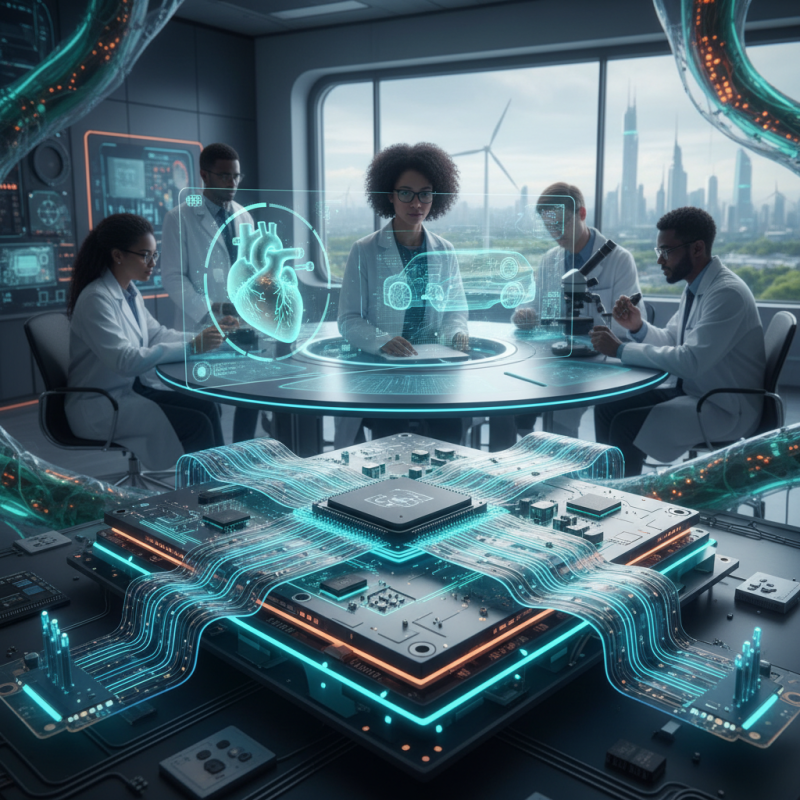

Looking ahead, several key trends are poised to emerge in the rigid flex PCB domain. From increased miniaturization to enhanced thermal management, these innovations aim to meet the growing demands of industries such as consumer electronics, automotive, and medical devices. Dr. Johnson emphasizes, “The next few years will see a shift towards more sustainable practices in rigid flex PCB production, which is crucial for our environment and the industry's future.”

As we explore the top innovations and insights influencing rigid flex PCBs in 2025, it is essential to understand how these advancements will not only improve existing applications but also pave the way for new possibilities in design and functionality. The forthcoming developments in this dynamic field promise to enhance connectivity and performance, setting the stage for a new era of electronic integration.

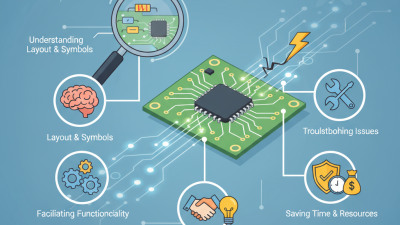

The landscape of rigid flex PCB design is poised for transformative advancements in 2025, driven by innovations that enhance functionality and reduce size. One notable trend is the integration of advanced materials that improve flexibility while maintaining structural integrity. Technologies such as high-density interconnect (HDI) and flexible substrates enable more compact designs, allowing manufacturers to create smaller, lighter devices without compromising performance. This push towards miniaturization is essential in meeting the demands of ever-evolving consumer electronics, automotive applications, and wearable technologies.

Another emerging area is the implementation of artificial intelligence in PCB design processes. AI-driven design tools are expected to streamline the development of rigid flex circuits by optimizing layouts and predicting potential failure points in real-time. This advancement not only enhances efficiency and speed in the design phase but also leads to improved reliability and longevity of the final products. Moreover, the rise of 5G technology and Internet of Things (IoT) devices necessitates PCBs with superior electrical performance, making innovative designs that support high-frequency applications increasingly critical in the marketplace.

The shift towards sustainable materials and manufacturing practices in rigid flex PCBs is increasingly gaining traction as the electronics industry aims to reduce its environmental footprint. According to a recent industry report, the global market for eco-friendly materials in electronics is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2023 to 2028. This growing demand is prompting manufacturers to explore alternatives such as bio-based epoxy resins and recycled materials, which not only lessen waste but also minimize harmful emissions during production.

Moreover, advancements in manufacturing techniques are paving the way for greener rigid flex PCB production. Innovations such as additive manufacturing and precision cutting are being adopted to reduce material waste and improve energy efficiency in the production process. A study from the Institute of Electrical and Electronics Engineers (IEEE) notes that implementing sustainable practices in PCB manufacturing can lead to a 30% reduction in energy consumption. As these trends gain momentum, it becomes imperative for industry players to integrate sustainable practices, ensuring their products meet the growing regulatory standards and consumer preferences for environmentally responsible electronics.

The advancements in connectivity and miniaturization for rigid flex printed circuit boards (PCBs) represent a significant leap forward in electronics technology. As the demand for compact and versatile designs in devices continues to rise, rigid flex PCBs are poised to meet these challenges by integrating multiple functions into a single unit. This integration not only reduces the physical size of the circuit boards but also enhances the reliability and performance of electronic systems. The ability to combine rigid and flexible elements allows for innovative product designs, enabling devices to achieve more complex configurations without compromising on functionality.

In 2025, we expect to see a surge in the use of advanced materials and manufacturing techniques that further promote miniaturization. The development of thinner and lighter substrates will facilitate the creation of smaller electronic components while maintaining high levels of durability and connectivity. Additionally, innovations in signal integrity and power management will contribute to more efficient communication between components, enhancing overall system performance. As industries seek solutions that offer both improved space utilization and functionality, rigid flex PCBs are set to become a cornerstone of modern electronics, driving forward the next generation of connected devices.

As the demand for rigid flex PCBs continues to rise, innovations in testing and quality assurance are becoming critical to ensuring their performance and reliability. One significant trend is the adoption of advanced non-destructive testing (NDT) methods. These techniques, which include X-ray and ultrasonic testing, allow for the inspection of the internal layers of rigid flex circuits without damaging them. By employing these technologies, manufacturers can identify defects early in the production process, thus minimizing costly errors and ensuring that the final products meet stringent quality standards.

Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) into testing frameworks is revolutionizing quality assurance in rigid flex PCBs. These technologies enhance the analysis of testing data, enabling quicker and more precise defect detection while reducing human error. Real-time monitoring systems powered by AI can provide instant feedback during the manufacturing process, ensuring that any anomalies are addressed proactively. This approach not only streamlines production but also significantly enhances the overall reliability of rigid flex PCBs, paving the way for their broader application across various industries.

| Innovation | Description | Expected Impact | Year of Implementation |

|---|---|---|---|

| Advanced Layer Stacking Techniques | Utilizing innovative methods to stack multiple layers for increased functionality. | Greater signal integrity and enhanced space utilization. | 2025 |

| AI-Driven Testing Protocols | Employing artificial intelligence to streamline testing processes and predict failures. | Reduced testing time and increased reliability of products. | 2025 |

| Automated Quality Assurance Systems | Integration of automated systems to monitor quality at each stage of production. | Consistency in product quality and reduced human errors. | 2025 |

| Flexible Materials Innovation | Developing new materials that enhance durability and flexibility of PCBs. | Improved longevity and performance in challenging environments. | 2025 |

| Enhanced Thermal Management Solutions | Innovations aimed at better heat dissipation in densely packed circuits. | Prevention of thermal damage and increased lifespan of electronics. | 2025 |

The innovation landscape of rigid flex printed circuit boards (PCBs) is rapidly evolving, particularly as enhanced customization capabilities become a focal point for manufacturers and end-users alike. With the increasing demand for tailored electronic solutions across diverse industries, rigid flex PCBs are now being designed to cater to specific application needs. This trend is leading to the development of more complex and bespoke designs that maximize performance and efficiency in space-constrained environments.

Enhanced customization is not just about the physical dimensions of the PCBs; it extends to the materials used and the integration of advanced technologies. Manufacturers are leveraging sophisticated design software and simulation tools that enable engineers to create highly specialized PCBs that meet unique industry requirements. This includes features such as embedded components, multilayer configurations, and improved thermal management systems. As a result, businesses can optimize their products for better functionality and longer life cycles, which is especially crucial in sectors like medical devices, wearables, and aerospace, where reliability and performance are non-negotiable.

Furthermore, application-specific rigid flex solutions are making significant strides in enhancing product usability and reducing manufacturing costs. By streamlining the assembly process and minimizing the need for additional components, these innovative designs offer significant logistical advantages. As industries continue to evolve and embrace the Internet of Things (IoT) and smart technology, the capacity for customization in rigid flex PCBs is set to play a pivotal role in pushing the boundaries of electronic design and functionality in the coming years.