In the rapidly evolving landscape of electronics, rigid flex PCBs have emerged as a pivotal component driving innovation across various industries. According to a recent market analysis by the IPC (Association Connecting Electronics Industries), the rigid flex PCB market is expected to grow at a CAGR of 10% over the next five years, reflecting the increasing demand for lightweight and compact electronic designs. This growth is largely attributed to their unique characteristics, such as superior flexibility, reduced manufacturing complexity, and enhanced reliability, which make them ideal for applications in consumer electronics, aerospace, and medical devices.

Industry expert Dr. Emily Harris, a leading figure in flexible circuit technology, emphasizes the significance of rigid flex PCBs: “As we see more miniaturization in electronics, the role of rigid flex PCBs becomes increasingly critical not only for performance but also for enabling innovative designs.” In 2023, understanding the top applications of rigid flex PCBs is essential for companies looking to stay competitive in the market. From automotive systems to portable medical instruments, the versatility of rigid flex PCBs is reshaping sectors and influencing the design considerations of engineers and manufacturers alike. This overview of the top 10 applications of rigid flex PCBs will illuminate how these advanced circuit boards are revolutionizing the way we interact with technology.

Rigid flex PCBs have become increasingly vital in the consumer electronics sector, largely due to their space-saving benefits and enhanced performance capabilities. According to a report by MarketsandMarkets, the global rigid flex PCB market is expected to grow from USD 8.3 billion in 2021 to USD 14.7 billion by 2026, reflecting a compound annual growth rate (CAGR) of 12.4%. This growth is primarily driven by the need for miniaturized devices that offer increased functionality without compromising reliability.

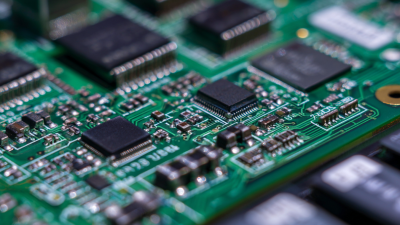

In consumer electronics, rigid flex PCBs are employed in a variety of applications including smartphones, tablets, and wearables. Their ability to integrate vertical space and enable multi-dimensional designs makes them ideal for compact devices where layout flexibility is crucial. Additionally, the lightweight nature of rigid flex designs improves portability, a key requirement in the increasingly mobile-first market. Reports indicate that nearly 60% of smartphone manufacturers are adopting rigid flex technology to enhance performance and reduce assembly complexity, ultimately leading to more reliable products in the hands of consumers.

Furthermore, emerging technologies such as IoT devices and smart home systems are amplifying the demand for rigid flex PCBs. The seamless integration of circuitry into complex shapes allows for innovative designs that support various functionalities like sensing, monitoring, and connectivity. As consumers continue to expect more advanced features in smaller packages, the role of rigid flex PCBs in revolutionizing product design and functionality in consumer electronics is undeniable.

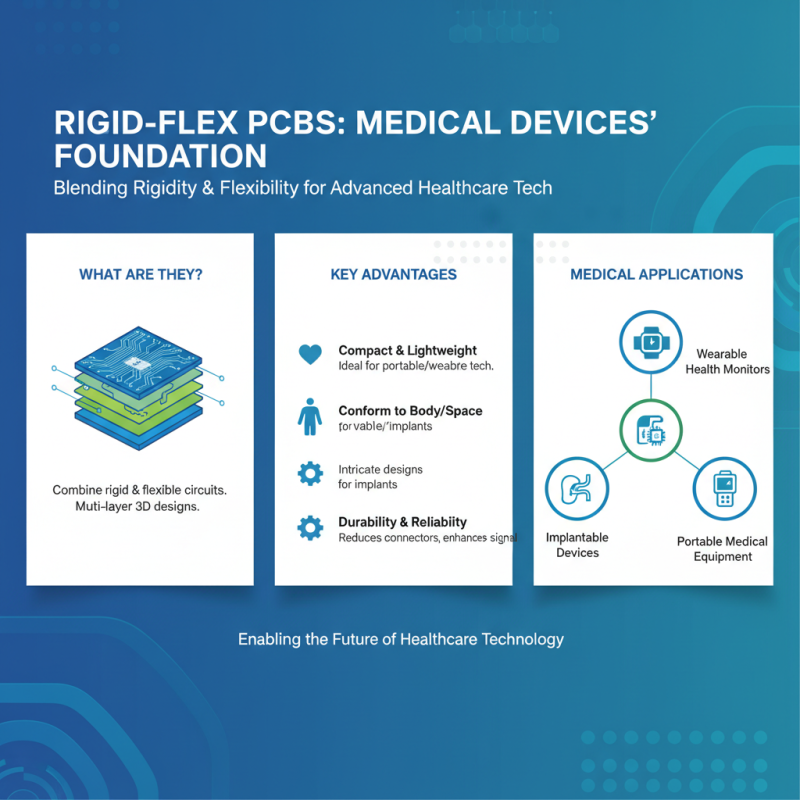

Rigid flex PCBs are increasingly becoming a cornerstone in the development of advanced medical devices due to their unique characteristics that combine the advantages of both rigid and flexible circuits. These types of PCBs are particularly valuable in portable medical equipment, where compact design and lightweight are crucial. For instance, devices like wearable health monitors and implantable medical devices benefit significantly from the flexibility of rigid flex designs, allowing for intricate layouts that can conform to the human body or fit into tight spaces.

Moreover, the use of rigid flex PCBs enhances reliability in medical applications. With their ability to withstand motion and bending, these circuits can reduce the risk of failure that might occur with traditional rigid boards. This reliability is paramount in applications such as robotic surgical tools and diagnostic equipment, where precision and durability are essential. As innovations continue to emerge in medical technology, the integration of rigid flex PCBs is likely to pave the way for more advanced functionalities, ultimately leading to improved patient outcomes and streamlined healthcare processes.

Rigid flex PCBs have become increasingly vital in aerospace and defense technologies, thanks to their unique combination of flexibility and durability. These advanced circuit boards are designed to withstand the harsh conditions typical of aerospace applications, such as extreme temperatures, vibration, and humidity. According to a report by the International Data Corporation (IDC), the demand for rigid flex PCBs in the aerospace sector is projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2022 to 2027. This growth is driven by the rising need for lightweight and space-efficient electronic systems that can improve the performance and reliability of aircraft and defense systems.

In addition, the integration of rigid flex PCBs in military applications enhances the operational efficiency of complex systems such as avionics and communication devices. These PCBs facilitate the design of compact and robust systems that can operate under extreme conditions, thus reducing maintenance costs and downtime. Research conducted by the National Aerospace Standards (NAS) indicates that rigid flex designs not only save valuable space within equipment but also contribute to lower overall weight, which is a critical factor in aerospace design. With their ability to support high-density interconnects and improve signal integrity, rigid flex PCBs are becoming indispensable in meeting the evolving demands of aerospace and defense technologies.

In the realm of aerospace and defense technologies, rigid flex PCBs are increasingly utilized across various applications. The data presented highlights the frequency of their application in ten key areas, illustrating the pivotal role they play in ensuring reliability and performance in critical systems.

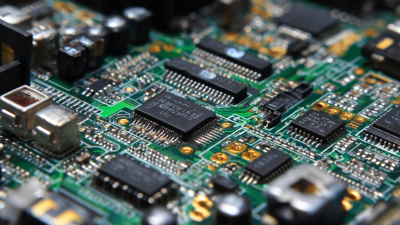

The automotive industry is witnessing a significant shift towards the integration of advanced electronics, which has greatly influenced the adoption of rigid flex printed circuit boards (PCBs). These PCBs offer a compact and lightweight solution, ideal for the challenging environments of automotive applications. According to the MarketsandMarkets report, the global rigid flex PCB market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 9.2% from 2020. This surge is driven by the increasing demand for electronic components in vehicles, especially with the rise of electric vehicles (EVs) and autonomous driving technologies.

One of the emerging trends in rigid flex PCB applications within the automotive sector is the growing need for high-density interconnects (HDI). As vehicles become more connected and reliant on advanced driver-assistance systems (ADAS), the complexity and number of electronic components are rising. Data from Research and Markets indicates that the adoption of ADAS is expected to reach a market value of USD 60 billion by 2025, leading to a corresponding increase in demand for innovative PCB solutions. Rigid flex PCBs facilitate efficient routing of signals and power distribution, thus enabling manufacturers to meet the stringent requirements for miniaturization without compromising performance and reliability. This trend underscores the essential role rigid flex PCBs will play in the future of automotive design and functionality.

| Application | Description | Trends | Benefits |

|---|---|---|---|

| Advanced Driver Assistance Systems (ADAS) | Integrates multiple sensors for enhanced vehicle safety and navigation. | Increase in demand for safety features. | Improved safety and reduced accident rates. |

| Infotainment Systems | Provides entertainment and information to the driver and passengers. | Shift towards connected car technologies. | Enhanced user experience and connectivity. |

| Electric Vehicle Control Systems | Manages electric drive and battery systems. | Growth of the electric vehicle market. | Increased efficiency and energy management. |

| Vehicle-to-Everything (V2X) Communication | Enables communication between vehicles and infrastructure. | Implementation of smart traffic management systems. | Improved traffic flow and reduced congestion. |

| Autonomous Driving Systems | Allows vehicles to drive themselves with minimal human intervention. | Advancements in AI and machine learning. | Potential for improved road safety and efficiency. |

| Telematics Systems | Monitors vehicle diagnostics and performance remotely. | Increased focus on vehicle maintenance and management. | Reduced operational costs and enhanced productivity. |

| Head-Up Displays (HUD) | Projects essential information onto the windshield. | Focus on driver-centered designs and safety. | Improved driver awareness and reduced distractions. |

| Battery Management Systems (BMS) | Monitors and controls the charging and discharging of batteries. | Growing popularity of hybrid and electric vehicles. | Enhanced battery lifespan and performance. |

| Electric Power Steering (EPS) | Controls vehicle steering electronically for better handling. | Increasing focus on performance and efficiency. | Improved fuel efficiency and reduced weight. |

| 360-Degree Cameras | Provides a complete view of the vehicle’s surroundings. | Growing importance of parking assistance and safety features. | Enhanced safety during maneuvers and parking. |

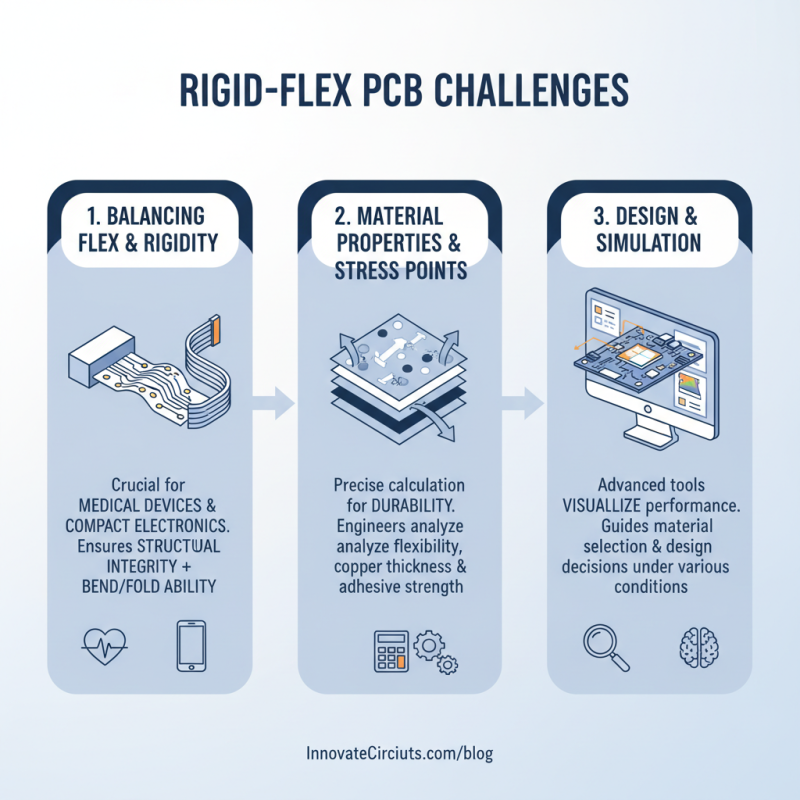

The manufacturing and design of rigid flex PCBs present unique challenges that require innovative solutions. One primary challenge is managing the delicate balance between flexibility and rigidity. This is crucial for applications that demand both structural integrity and the ability to bend or fold, such as in medical devices and compact consumer electronics. Engineers must precisely calculate the materials' properties and the intended stress points to ensure durability without compromising functionality. Advanced simulation tools can help visualize performance under various conditions, guiding design decisions and material selection.

Another significant challenge lies in the interconnection of layers within a rigid flex PCB. Achieving reliable connections between rigid and flexible sections can be complex due to differing thermal expansion rates, which may lead to mechanical stress and potential failure. Solutions may involve sophisticated bonding techniques or the adoption of hybrid materials that can withstand the stresses of thermal cycling. Furthermore, careful attention to the manufacturing process, including the use of automated inspection technologies, can detect potential issues early, reducing the risk of defects and enhancing product reliability. Addressing these challenges effectively enables the successful deployment of rigid flex PCBs across diverse industries, paving the way for innovative designs and advanced functionalities.