In the fast-evolving landscape of electronics, the importance of reliable and high-quality PCB fabrication services cannot be overstated. As technology advances, the demand for precision-engineered printed circuit boards (PCBs) has surged, making it crucial for businesses to partner with the right PCB fab services. According to Dr. Emily Chang, a leading expert in the PCB fabrication industry, “Quality isn’t just a goal; it’s the foundation of successful electronics manufacturing.” Her insights underline the necessity for companies to prioritize both quality and efficiency in their PCB fab processes.

The year 2023 has witnessed significant developments in PCB fabrication, with many services innovating to meet the rigorous standards set by the industry. Companies are now more than ever seeking to balance cost-effectiveness with advanced manufacturing techniques. This article will explore the top 10 PCB fab services that stand out in providing exceptional quality and efficiency. By analyzing these leading providers, we aim to equip readers with the knowledge to make informed decisions in selecting PCB fabrication partners that align with their project requirements and business objectives.

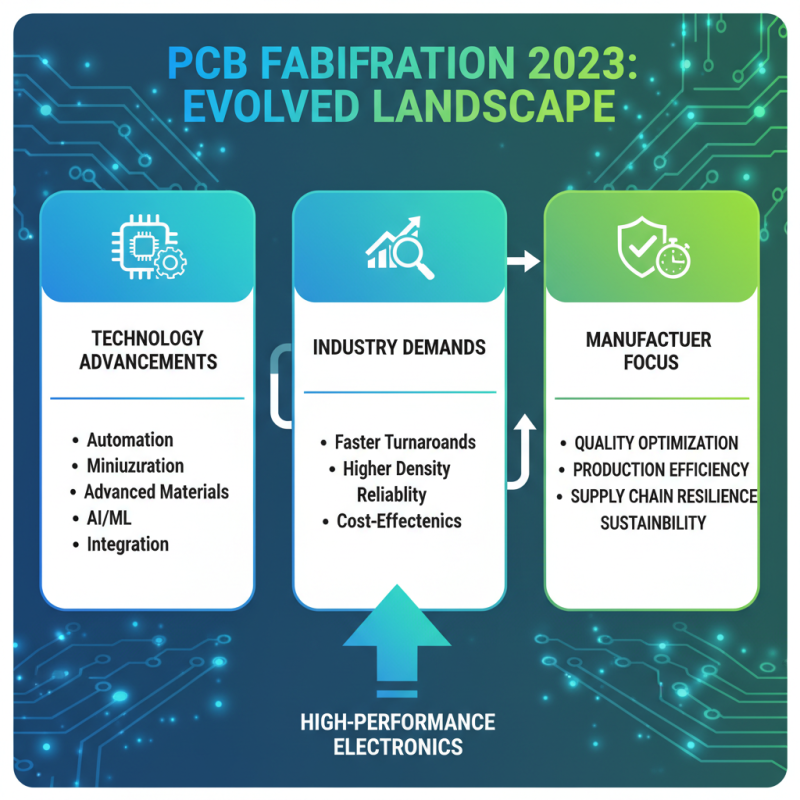

The landscape of PCB fabrication services in 2023 has evolved significantly, driven by advancements in technology and escalating industry demands. As the electronic market becomes increasingly competitive, manufacturers are focusing on delivering high-quality printed circuit boards (PCBs) paired with efficient production processes. This dual emphasis on quality and efficiency ensures that companies can meet tight deadlines while maintaining superior standards in their products.

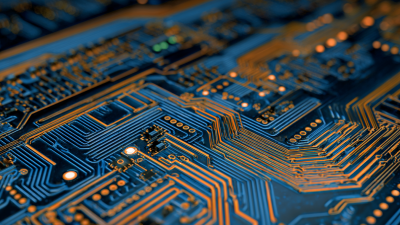

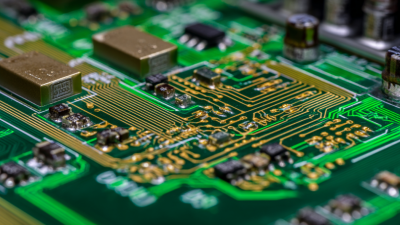

One of the key trends observed in the PCB fabrication sector is the integration of automated processes, which enhance accuracy and reduce production time. Techniques such as advanced laser cutting and automated assembly are now standard, allowing for rapid prototyping and quick turnarounds on orders. Moreover, manufacturers are adopting strict quality control measures, utilizing sophisticated testing methods to ensure that every PCB meets industry standards. This commitment to excellence not only boosts customer satisfaction but also fosters long-term partnerships in a market where reliability is paramount.

Additionally, the push for sustainability is reshaping the practices of PCB fabs, with many companies now prioritizing eco-friendly materials and processes. As environmental concerns continue to escalate globally, the PCB industry is responding by minimizing waste and enhancing energy efficiency during production. These shifting dynamics reflect a broader movement within the tech industry to align with sustainable practices, making it imperative for PCB fabrication services to adapt swiftly to these new expectations while maintaining their competitive edge.

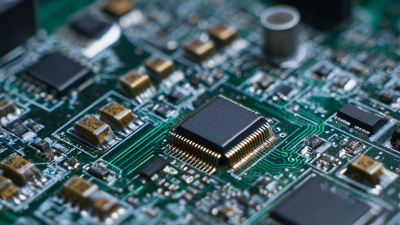

When evaluating the quality in PCB fabrication, several criteria must be considered to ensure that the final product meets the required standards and specifications. Firstly, material selection plays a crucial role, as the substrate used can significantly impact the performance and reliability of the PCB. Components such as FR-4, Rogers, or aluminum may be chosen based on electrical, thermal, and mechanical properties essential for the specific application. Additionally, the fabrication process itself, including the precision of etching, lamination, and drilling, must adhere to strict tolerances to avoid defects.

Another critical aspect to assess is the quality control measures implemented during fabrication. A robust quality assurance process includes thorough testing methods such as electrical testing (e.g., flying probe or ICT), visual inspections, and mechanical inspections to guarantee that the PCBs function as intended. Certifications, such as ISO 9001 or IPC standards, may also indicate a company’s commitment to maintaining high-quality processes. Furthermore, the ability to provide detailed documentation and traceability throughout the production stages can be a significant factor for businesses looking to ensure reliability and quality in their PCB sourcing.

In today's rapidly evolving electronics landscape, reliability and efficiency in printed circuit board (PCB) fabrication are paramount for businesses looking to stay competitive. A recent industry report indicates that the global PCB market is projected to reach

$84 billion by 2028, with a significant emphasis on high-quality manufacturing processes. This soaring demand underscores the need for fabricators who can not only meet production deadlines but also ensure that the boards produced meet

stringent quality standards.

Efficiency in PCB fabrication directly correlates with advanced manufacturing techniques. Automation, for instance, has reduced the production time for PCBs by up to 30% in some cases, allowing manufacturers to respond more quickly to market demands. Moreover, the adoption of

lean manufacturing principles has helped many fabricators optimize their supply chains and minimize waste, further enhancing their reliability. According to a report by a leading market research firm, companies that implement these practices

see a reduction in operational costs by as much as 20%, highlighting the importance of choosing partners that prioritize efficiency alongside product integrity.

In the ever-evolving landscape of PCB fabrication, selecting the right service provider is crucial for achieving the desired quality and efficiency. Leading PCB fab companies typically offer a range of services designed to cater to various project needs, including rapid prototyping, production runs, and advanced technology integration. Many manufacturers emphasize quick turnaround times, which is essential for keeping up with the fast-paced demands of the electronics market. Additionally, the capabilities of these companies often extend to specialized processes such as multilayer boards, HDI technology, and the use of a diverse array of materials, ensuring that they can meet the specific requirements of different applications.

Quality assurance is a key factor that distinguishes top PCB fab services. Most providers implement rigorous testing protocols, including Electrical Test (E-Test) and Automated Optical Inspection (AOI), to ensure reliability and performance. Furthermore, certifications such as ISO 9001 and IPC standards are common benchmarks that signal a company’s commitment to quality. Alongside these assurances, some services offer tailored customer support, where clients can engage with engineers throughout the design and manufacturing process. This collaborative approach helps to streamline communication and address any potential issues promptly, thus enhancing overall efficiency and satisfaction in the PCB fabrication journey.

The landscape of PCB fabrication is rapidly evolving, marked by innovative technologies aimed at boosting quality and efficiency. Advancements such as automated fabrication processes and the incorporation of artificial intelligence into design and manufacturing workflows are reshaping how electronic components are produced. According to a recent market analysis report by Smithers Pira, the global PCB market is projected to reach $82 billion by 2025, driven largely by the increasing demand for smart devices and IoT applications. This not only underscores growing consumer needs but also highlights the necessity for manufacturers to adopt faster, more efficient production methods.

As we look toward future trends, one significant development is the rise of additive manufacturing technologies in PCB fabrication. These technologies allow for more intricate designs and enhanced customization without the extensive time and cost that traditional methods entail. Additionally, industry experts predict a greater emphasis on sustainability, with companies increasingly focused on reducing waste and employing eco-friendly materials in their processes. This trend aligns with a broader shift in the electronics industry aimed at minimizing the environmental impact of production activities.

Tips: When selecting a PCB fabrication service, consider their investment in advanced technologies and sustainability practices. Look for services that offer rapid prototyping and quick turnarounds to keep pace with market demands. Furthermore, collaborating with manufacturers who prioritize innovation can significantly enhance your product’s quality and reliability.