In today's rapidly evolving electronics landscape, the demand for high-quality circuit board manufacturing is more critical than ever. A report from IPC—Association Connecting Electronics Industries revealed that the global PCB market is projected to reach $85 billion by 2025, highlighting the significant growth potential in the PCB fab industry. As manufacturers strive to meet the increasing demands for precision and efficiency, identifying the best PCB fab services becomes an essential consideration for businesses looking to maintain a competitive edge.

As noted by renowned industry expert Dr. Susan Wei, "The quality of the PCB fab process directly influences the overall performance and reliability of electronic devices." Her insights shed light on why selecting a proficient PCB fab service is crucial; it not only affects production timelines but also ensures that the final product adheres to stringent specifications. The top PCB fabrication services are characterized by advanced manufacturing techniques, stringent quality control measures, and an ability to deliver innovative solutions—all of which are fundamental in shaping the future of electronic manufacturing. With the projected growth and technological advancements in the field, companies must stay informed and choose wisely to secure their operations in this competitive market.

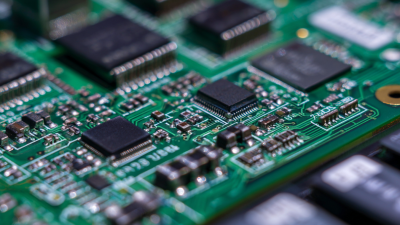

When evaluating PCB fabrication services, quality is paramount. A comprehensive assessment should consider factors such as manufacturing precision, turnaround time, and customer service. The most reputable PCB fab services prioritize advanced technology and skilled labor to ensure high-quality production. Companies are investing in state-of-the-art manufacturing plants, which enhance efficiency and reduce costs, while also providing insights into capital investments, operational expenses, and expected return on investment.

Moreover, user experiences and reviews play a crucial role in determining the best PCB fabrication services. Personal testimonials reflect actual performance and quality, highlighting how companies like PCBWay excel in prototype services. By gathering feedback from a broad range of users, it becomes clear which companies consistently meet the demands of both hobbyists and professional engineers. With the ongoing growth in the electronics manufacturing industry, selecting a service that emphasizes quality ensures a reliable foundation for electronic projects.

This chart displays the quality scores of various PCB fabrication services based on a comprehensive evaluation of factors such as reliability, turnaround time, customer support, and overall satisfaction. The scores represent a ranking from 1 to 10, where a higher score indicates better performance.

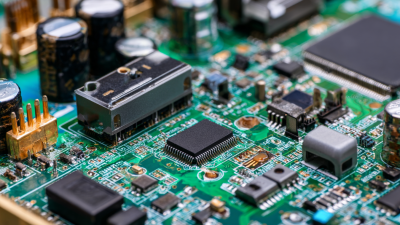

When selecting a PCB fabrication service, understanding the key industry standards and certifications is paramount to ensuring high-quality manufacturing. Look for services that comply with internationally recognized standards such as IPC-A-600, which specifies the acceptability of printed boards. This certification confirms that the circuit boards are manufactured to rigorous quality levels, minimizing defects and ensuring reliability in performance.

Another crucial standard is ISO 9001, which demonstrates an organization’s commitment to quality management systems. PCB fab services with this certification consistently meet customer and regulatory requirements, reflecting their dedication to continuous improvement. Additionally, compliance with RoHS (Restriction of Hazardous Substances) is essential for PCB manufacturers looking to produce environmentally friendly products that are free from harmful materials.

The choice between rigid and flexible printed circuit boards (PCBs) is vital for manufacturers aiming to optimize performance and reduce costs. Rigid PCBs, which dominate the market, account for approximately 80% of the PCB production volume, primarily due to their widespread use in electronics such as computers and televisions. These boards are known for their robustness and durability, making them ideal for applications that require a stable structure. A report from IPC indicates that the global rigid PCB market is projected to reach $65 billion by 2025, driven by advancements in technology and increasing demand for consumer electronics.

On the other hand, flexible PCBs have been gaining traction due to their versatility and lightweight design. Flexible boards represent about 20% of the market currently, but their use in smartphones, wearable devices, and medical equipment is driving a compound annual growth rate (CAGR) of over 10% for the segment. Their ability to bend, twist, and conform to compact spaces allows for innovative designs that rigid PCBs cannot accommodate. As reported by Research and Markets, the flexible PCB market is expected to surpass $30 billion by 2026, highlighting the shift towards customization and miniaturization in electronic design. These contrasting characteristics underline the critical decision faced by engineers and designers when selecting the appropriate PCB type for their specific applications.

The choice of materials in PCB manufacturing is pivotal, influencing not only performance but also the longevity of the circuit boards. For instance, a report by IPC, the global association for electronics manufacturing, highlights that using high-quality FR-4 materials can enhance thermal stability and reduce losses by up to 50% compared to inferior alternatives. Additionally, the right dielectric and copper thickness can significantly affect the overall signal integrity, ensuring reliable operation in high-frequency applications.

Moreover, the selection of specific materials can directly impact a PCB's lifespan. A study by the Electronic Industry Citizenship Coalition (EICC) indicates that PCBs made with advanced materials such as Rogers' dielectric materials can maintain their performance longer under thermal and environmental stress, with failure rates decreasing by 30% over a five-year period when subjected to harsh conditions. As manufacturers continue to innovate, understanding material properties becomes crucial for achieving durability and efficiency in circuit board applications.

When evaluating PCB fabrication services, a comprehensive cost-benefit analysis is essential for making informed decisions in 2023. The leading PCB fab services offer a variety of pricing models that cater to different project scales, from small batches to large production runs. Firms like PCBWay and JLCPCB are known for their competitive pricing and high-quality outputs, providing a significant advantage for businesses looking to minimize costs while ensuring reliability in their circuit boards. The trade-off between cost and quality plays a crucial role, as opting for the cheapest service may lead to issues down the line, impacting overall project timelines and product performance.

In addition to price, factors such as lead time, customer support, and additional services like assembly and testing should be considered. Companies that offer a one-stop solution can save time and reduce logistical complexities, which ultimately adds value beyond just the initial cost. For instance, services like Oshpark provide high-quality boards with a focus on customer experience, which can justify a higher price point. Thus, a thorough analysis of both financial investment and the benefits derived from each service is key to selecting the right PCB fabrication partner in a competitive market.

| Service Provider | Manufacturing Quality | Lead Time (Days) | Cost per PCB ($) | Customer Rating (1-5) |

|---|---|---|---|---|

| Provider A | High | 7 | 25 | 4.8 |

| Provider B | Medium | 10 | 18 | 4.5 |

| Provider C | High | 5 | 30 | 4.9 |

| Provider D | Medium | 8 | 22 | 4.3 |

| Provider E | High | 6 | 28 | 4.7 |

| Provider F | Low | 12 | 15 | 3.8 |

| Provider G | Medium | 9 | 20 | 4.2 |

| Provider H | High | 4 | 35 | 4.6 |

| Provider I | Low | 15 | 12 | 3.5 |

| Provider J | Medium | 11 | 19 | 4.1 |