In today's technology-driven world, printed circuit boards (PCBs) play a crucial role. They are the backbone of modern electronic devices, enabling functionality and connection. Many manufacturers produce high-quality PCBs, but not all meet industry standards. Choosing the right manufacturer can be challenging.

When searching for the best PCB makers, consider factors like reliability, quality, and price. Some companies excel in specific applications, while others cater to a broad range. Small businesses might struggle to find the right partner. It's not just about cost; quality matters significantly.

PCBs can vary greatly in complexity. Some are simple, while others require advanced engineering. Identifying the right printed circuit board manufacturer is vital for success. Be aware of the challenges involved. Choose wisely to ensure your project thrives in a competitive market.

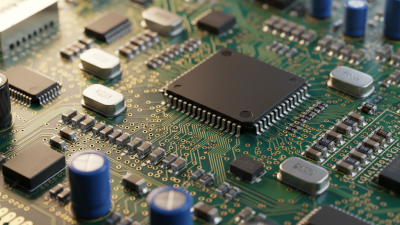

Printed Circuit Boards (PCBs) are integral to modern electronics. They provide pathways for electrical signals. Without them, devices like smartphones and computers would not function. The design and manufacturing of PCBs require precision and expertise. Every connection matters in a circuit. Slight defects can lead to significant problems, such as malfunctioning devices.

PCBs come in various forms. Some are simple, while others are incredibly complex. Multi-layer boards can house thousands of components. The challenges in smart designs often lead to unexpected issues. It's common to overlook minor details during manufacturing, which can cause failures down the line. Engineers face pressure to innovate quickly, which might compromise quality. This aspect makes it crucial to choose reliable manufacturers. Their experience can prevent costly mistakes and ensure device longevity.

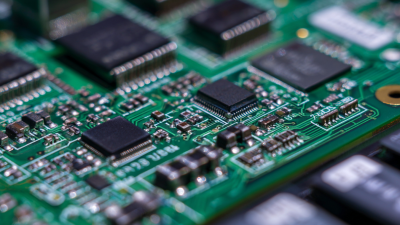

The importance of PCBs cannot be overstated. They support both simple and advanced technologies. As electronics evolve, so do the demands on PCB manufacturing. The quest for higher efficiency and miniaturization continues. Finding balance remains challenging. New materials and techniques emerge constantly. Often, the industry struggles to keep pace with these advancements while maintaining quality and cost-effectiveness.

| Manufacturer | Location | Year Established | Specialization | Certifications | Website |

|---|---|---|---|---|---|

| Company A | USA | 1985 | High-Density Interconnect | ISO 9001 | www.companya.com |

| Company B | Germany | 1990 | Flexible PCBs | UL, ISO 13485 | www.companyb.com |

| Company C | China | 2000 | Multilayer PCBs | ISO 9001, RoHS | www.companyc.com |

| Company D | Japan | 1995 | Rigid Boards | ISO 9001 | www.companyd.com |

| Company E | Canada | 1988 | Prototype PCBs | ISO 9001, IPC | www.companye.com |

| Company F | South Korea | 1993 | Advanced PCBs | ISO 14001 | www.companyf.com |

| Company G | USA | 1980 | High-Frequency PCBs | ISO 9001, IPC | www.companyg.com |

| Company H | India | 2005 | Budget PCBs | ISO 9001, RoHS | www.companyh.com |

| Company I | UK | 1997 | Custom PCB Designs | ISO 9001 | www.companyi.com |

| Company J | Taiwan | 1992 | Automotive PCBs | ISO 9001, IATF 16949 | www.companyj.com |

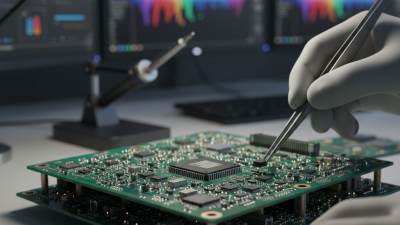

Choosing the right printed circuit board (PCB) manufacturer requires careful consideration of several key factors. Quality is paramount. Ensure that the manufacturer has rigorous quality control processes. Look for certifications that demonstrate compliance with industry standards. Reliability in production timelines is another critical factor. Delays can disrupt your entire project timeline. A manufacturer with a consistent track record of timely delivery can save you headaches.

Additionally, flexibility and communication play vital roles. The best manufacturers can adapt to changes in design or order size. They should be responsive and open to discussions throughout the process. Transparency regarding pricing and potential hidden costs is essential. You should never be surprised by the final invoice.

Finally, examine their technological capabilities. A manufacturer with advanced machinery and equipment can offer improved precision and faster production speeds. However, don’t overlook customer reviews and past work samples. They provide insight into the manufacturer's reliability and performance. Reflect on your specific needs. The ideal manufacturer should align with your project goals while ensuring quality and efficiency. Balancing cost and excellence remains a constant challenge.

When considering the best printed circuit board (PCB) manufacturers, a few key factors emerge. Quality and reliability are essential. In an industry where precision is vital, manufacturers must ensure their products meet stringent standards. A single error in a PCB can lead to significant issues further down the line.

Some manufacturers excel in rapid prototyping. This allows companies to test their designs faster. However, not all are equipped to handle large volume orders effectively. This disparity can lead to frustration, especially when deadlines loom. The ability to scale production without sacrificing quality is a challenging balance.

Customer service is also vital in the PCB industry. Effective communication can solve problems quickly. Yet, some manufacturers struggle to respond promptly. This impacts collaboration and trust. Transparency in processes can make a significant difference. Understanding the manufacturer’s capabilities can help businesses make informed decisions about partnerships.

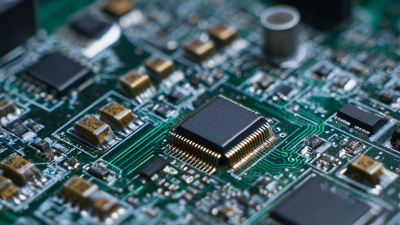

When choosing a printed circuit board (PCB) manufacturer, it's vital to understand the key features these companies offer. Quality assurance is fundamental. According to industry reports, nearly 70% of PCB failures arise from manufacturing defects. Manufacturers often implement strict testing protocols to minimize these risks. Engineers should inquire about certifications like ISO and IPC compliance. This ensures the highest standards are upheld.

Another crucial factor is design support. Many leading manufacturers provide design assistance. They may help optimize layouts and reduce costs. This collaboration can significantly impact the end product's success. Cost estimates based on specific criteria, such as volume and complexity, are often provided. Understanding this can save valuable time and resources for designers.

Tip: Before finalizing a choice, request prototypes. This step can reveal potential design flaws and manufacturing challenges. Many firms adopt flexible production processes, allowing for quick adjustments. Consumers should verify the scalability of these services. The PCB market is projected to grow by over 7% annually. Yet, not every manufacturer can keep pace with increasing demands. Careful research can uncover hidden limitations in capabilities.

The future of printed circuit board (PCB) manufacturing is evolving rapidly. Innovations like advanced materials and smart manufacturing techniques are now essential. Companies are investing in automation to enhance production efficiency. Automation helps reduce human error and increases output speed. However, the integration of technology is not without challenges. Ensuring quality control remains a pressing issue.

Another trend is the move toward sustainable practices. Manufacturers are focusing on green materials to reduce environmental impact. Yet, the shift to sustainable methods can be complicated and costly. Many companies struggle to balance cost with eco-friendliness. Proper training and education of personnel is also crucial in this transition.

Moreover, miniaturization is becoming increasingly significant. As devices shrink, the demand for smaller, more intricate PCBs rises. Designing these mini-PCBs presents significant technical hurdles. Engineers constantly need to rethink traditional designs. Collaboration among engineers, designers, and manufacturers is vital for success. It's a complex but fascinating time in the world of PCB manufacturing.