In the fast-evolving world of electronics, PCB assembly stands as a cornerstone for success. Renowned expert Dr. Jane Williams, a leader in PCB technology, emphasizes, “Without effective PCB assembly, product failure is often inevitable.” This illustrates just how vital this process is for manufacturing excellence.

Every electronic device relies on printed circuit boards (PCBs) to function properly. The assembly of these components is critical. Yet, many businesses overlook its importance. Poor assembly can lead to defects and higher costs. This not only harms the product but also the reputation of the company.

Consider the impact of advanced automation in PCB assembly. While it boosts efficiency, it can also introduce new challenges. A lack of skilled technicians may occur. Without their expertise, the benefits of automation can be lost. This highlights a need for balance in the industry. Focusing solely on technology may overlook the human element required for quality assurance.

PCB assembly plays a pivotal role in the electronic manufacturing sector. According to industry reports, it accounts for roughly 40% of the total production costs. A well-executed assembly process ensures better functionality and reliability of electronic devices. However, many manufacturers still face challenges in quality control.

Inadequate training or poor equipment can lead to defects. For example, a report by IPC highlights that 60% of PCB defects originate from assembly errors. These mistakes can be costly, leading to substantial rework and wasted materials. Companies often overlook these issues, resulting in even greater long-term losses and customer dissatisfaction.

The demand for high-quality PCBs continues to rise. A New Market Insights report predicts that the global PCB market will exceed $80 billion by 2026. This growth pushes manufacturers to improve assembly processes. Yet, not all are keeping pace. Many struggle with outdated methods, which can hinder innovation. Continuous reflection on these practices is essential for future success.

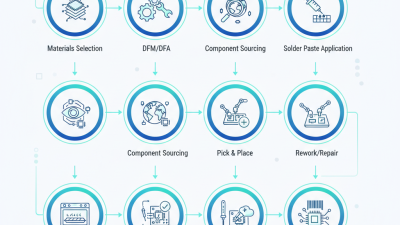

PCB assembly is a vital step in electronic manufacturing. The process includes several key stages that ensure a functioning product. Each stage requires attention to detail. One critical phase is soldering. According to industry reports, improper solder joints account for nearly 50% of product failures. This highlights the importance of precision.

Another essential process is component placement. Automated machines often achieve accuracy rates above 99%. However, human error still plays a role. Misaligned components can lead to significant issues. In fact, research indicates that a mere 0.5 mm misalignment can cause a malfunction. Quality control checks are crucial at this stage.

Testing follows assembly, which validates the functionality of devices. However, many companies overlook this step. Around 30% of firms do not conduct thorough testing. This neglect can lead to costly recalls and damage to reputation. Emphasizing these processes can enhance the reliability of electronic products. Without robust PCB assembly practices, manufacturers risk delivering faulty devices to their customers.

The design of a printed circuit board (PCB) plays a crucial role in assembly efficiency. A well-designed PCB can simplify the assembly process. It reduces the risk of errors and minimizes assembly time. This efficiency translates into cost savings and faster production cycles. An optimal layout ensures that components are placed correctly, avoiding the need for rework.

On the other hand, poor design choices can lead to complications. Misaligned components or an overcrowded layout can cause delays. These mistakes may not only waste time. They can also increase material costs due to damaged parts. Engineers need to focus on design clarity and modularity. It can feel challenging to balance size constraints with functionality. However, embracing these challenges can lead to innovative solutions that enhance assembly efficiency.

Additionally, the choice of materials matters. Using materials that are easy to handle can improve the assembly process. Complex components may look appealing on paper, but can be a nightmare during assembly. Emphasis must be placed on adaptability and usability. Reflecting on past projects can provide valuable insights into design weaknesses. Ultimately, those insights can improve future PCB assemblies immensely.

PCB assembly plays a vital role in electronic manufacturing. Yet, several challenges can arise during the process. One common issue is component misalignment. This can lead to poor connections, affecting device performance. Regular inspection is crucial. Implementing automated systems can help detect these misalignments early.

Another challenge is managing the supply chain for components. Delays or shortages can halt production. Manufacturers should maintain good relationships with suppliers. Having alternative suppliers can mitigate risks. Flexibility is key to sustaining production schedules.

Tips: Always double-check component placements. Use quality control measures to minimize errors. Engage in continuous communication with your team. Building a robust process helps identify and tackle potential issues proactively. When problems do arise, reflect on them. Each mistake offers a chance to improve.

The landscape of PCB assembly is evolving rapidly. Automation is becoming central. Advanced machines streamline the assembly process. However, not all manufacturers adopt these technologies seamlessly. Some struggle with integration. This can lead to inefficiencies and increased costs.

Quality control remains a significant concern. With rising complexity in designs, ensuring every connection is perfect is essential. Yet, human error can occur. This is a reality in many assembly lines today. Manufacturers must invest in both training and technology. Balancing the two is critical.

Sustainability trends are also noteworthy. Many companies aim for greener practices. This can be challenging. Proper waste management and material sourcing require effort. Not all manufacturers have the resources to adapt quickly. The push for efficiency must align with eco-friendly approaches. This balance is key for future success in PCB assembly.