In the fast-paced world of product development, speed and precision are crucial. This is where prototype PCB assembly plays a vital role. It serves as an essential step for engineers and designers. By creating initial versions, teams can identify flaws early. This early testing saves time and resources.

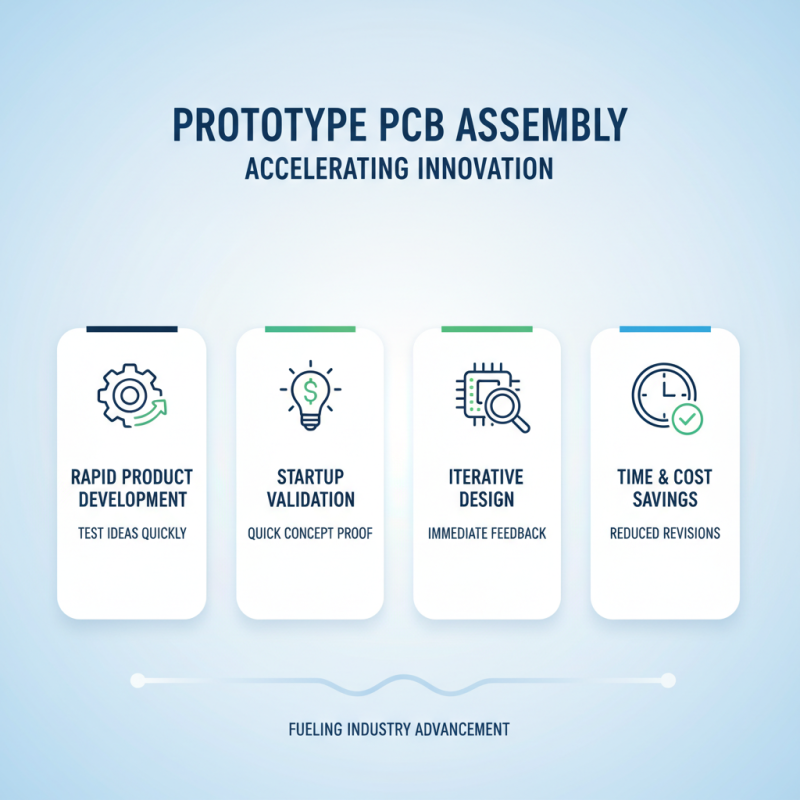

Prototype PCB assembly allows for rapid iterations. These iterations are necessary to refine product designs before mass production. It provides a tangible version of theoretical ideas. Teams can conduct real-world tests and gather user feedback. Such insights drive improvements and enhance overall quality.

However, not all prototype PCB assembly processes are perfect. Some companies may rush the assembly, leading to issues. It's important to reflect on these shortcomings. Each prototype offers lessons. Learning from these experiences is key to developing successful products. Ultimately, embracing the prototype PCB assembly process can lead to innovative solutions and market success.

Prototype PCB assembly plays a crucial role in product development. It allows engineers to test their designs quickly. Rapid iterations can reduce time to market significantly. With prototype assemblies, teams can identify flaws early. This early detection avoids costly revisions later. Speed is an essential factor in today’s competitive landscape.

Additionally, prototype assembly makes design adjustments easier. Engineers can experiment with different components without major commitments. However, challenges can arise. Sometimes, prototypes may not function as expected. This can lead to frustrations and delays. Each failure offers a learning opportunity. Teams must analyze what went wrong and adapt. The process can be iterative and messy but ultimately rewarding.

Engaging in prototype PCB assembly fosters innovation. Designers can push the boundaries of what's possible. Close collaboration between teams is vital. Regular feedback loops ensure everyone is on the same page. However, the path is not always smooth. Miscommunication can derail efforts. A solid plan and open dialogue are essential for success.

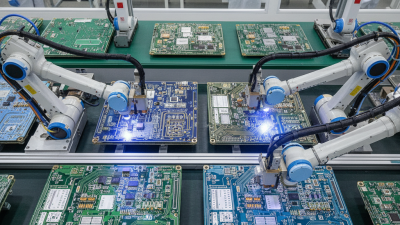

Rapid prototyping in electronic design is crucial. It allows engineers to create PCB prototypes quickly. This speeds up the testing phase and reduces time to market. Teams can identify issues early, leading to better products. Rapid PCB assembly aids in this process by providing functional designs.

Tips: Use simple materials for initial prototypes. This can lower costs and speed up assembly.

A major benefit of rapid prototyping is iteration. Designers can test multiple versions in a short time. Each version can improve upon the last, refining features and enhancing functionality. Motivation can wane during long projects. Regular prototypes can reinvigorate a team's focus and commitment to innovation.

Tips: Encourage team brainstorming after each prototype. Fresh ideas often emerge from discussions.

However, rushing can lead to mistakes. It's vital to maintain quality despite speed. Some designs may not work as planned. Learn from these setbacks. Gather feedback and adjust specifications carefully. What initially seems like a failure may offer valuable insights for future designs.

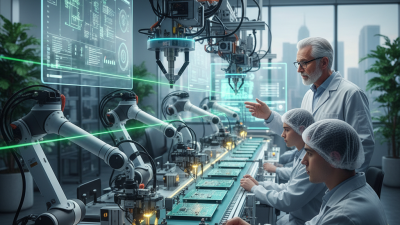

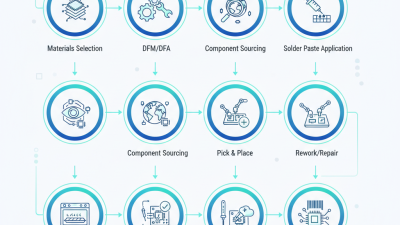

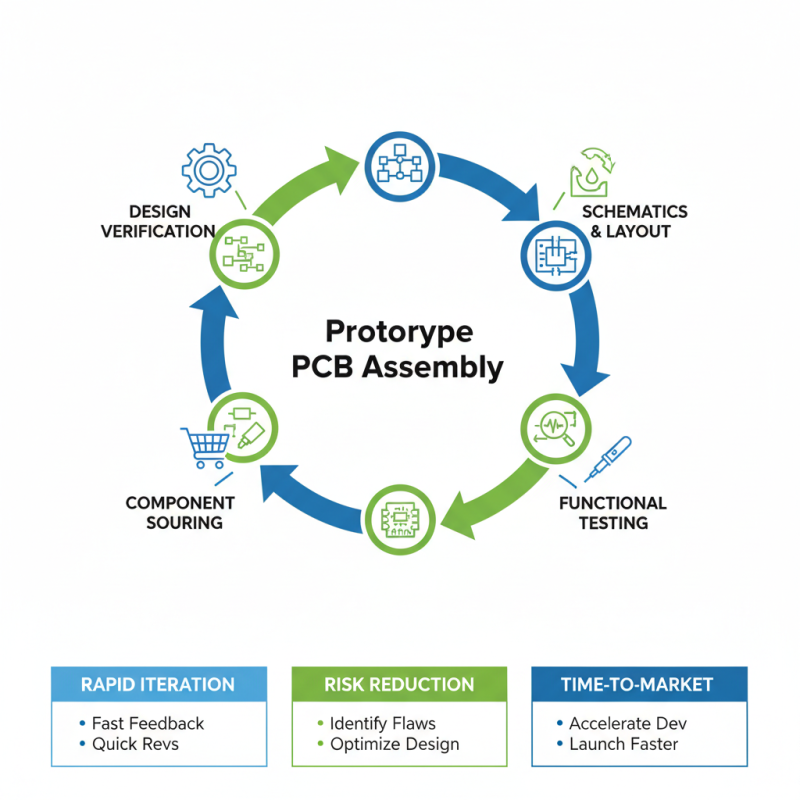

Prototype PCB assembly is a critical step in the rapid product development process. The journey typically begins with design verification. Engineers create and test a robust PCB design to identify potential flaws. Using software tools, they generate schematics and layouts that are refined until the design meets all specifications.

Next is the sourcing of components. Fabricators must find reliable suppliers for each component, ensuring quality and availability. This can be challenging. Sometimes, components may go out of stock or face delays. Companies often report that 30% of their project timeline is spent on sourcing. Therefore, maintaining a well-curated list of suppliers can help mitigate risks.

Once all components are in hand, assembly takes place. A combination of manual labor and automated machines is used here. Attention to detail is crucial. Even tiny errors can lead to significant performance issues. Regular inspections during assembly can catch these problems early. Tips include cleaning the work area and double-checking polarity on components, reducing mistakes.

Finally, testing ensures that the prototype functions correctly. This process involves rigorous evaluation against initial design requirements. However, it’s important to note that testing may reveal design flaws. These findings should lead to revisions of the original design. Learning from these iterations is vital for successful product development.

Prototype PCB assembly plays a crucial role in speeding up product development. However, several challenges can complicate this process. According to industry reports, 35% of engineers encounter issues with component shortages. This can delay timelines and increase costs. Access to the right components is vital. Visibility into supply chains has become essential for timely assemblies.

Another significant challenge is the risk of design errors. Studies indicate that 70% of product failures come from design flaws. Mitigating these requires thorough testing and iterative design processes. Utilizing advanced simulation tools can help identify flaws early. Many engineers still rely on traditional methods, leading to missed improvements and inefficiencies.

Additionally, quality control remains a consistent hurdle. A staggering 50% of prototype batches experience defects. This disrupts progress and wastes resources. Implementing automated inspection systems can enhance accuracy. Yet, many companies hesitate to invest in such technologies. The reluctance often stems from cost concerns. An investment in quality may seem daunting but often pays off in the long run. Addressing these challenges head-on is critical for successful prototype PCB assembly.

| Challenge | Impact | Solution | Additional Notes |

|---|---|---|---|

| Component Sourcing | Delays in production timeline | Establishing relationships with multiple suppliers | Consider local suppliers for faster access |

| Design Iterations | Increased development costs | Using flexible PCB design software | Emphasize modular design to ease changes |

| Testing and Validation | Risk of product failures | Implement thorough testing protocols | Utilize automated testing tools where possible |

| Manufacturing Limitations | Compromise on design quality | Choose advanced manufacturing techniques | Evaluate prototyping partners for capabilities |

| Communication Gaps | Misalignment between teams | Adopt collaborative project management tools | Regular progress meetings to keep everyone aligned |

Prototype PCB assembly plays a vital role in various industries. It accelerates product development cycles significantly. In the tech industry, it allows engineers to test their ideas rapidly. Many startups use prototype PCBs to validate concepts quickly before full-scale production. Immediate feedback from prototypes can lead to necessary changes in design. This can save time and resources in the long run.

Consider the automotive sector. Companies rely heavily on prototype PCBs for advanced electronics. These boards facilitate testing in real-world conditions. However, the process can sometimes result in flaws that need addressing. Engineers may overlook minor details during fast-paced development. These imperfections can lead to delays. Reflecting on these challenges is crucial for continuous improvement.

In the medical device industry, prototype PCBs are essential too. They ensure that electronic components meet strict regulations. Designers can simulate how devices interact with patients. This testing phase can reveal unexpected issues. Learning from these mistakes is important for safety and efficiency. Actual usage data is invaluable for refining products.