In the fast-evolving world of electronics, understanding different types of PCB boards is crucial. According to a recent market report by IPC, the PCB market is expected to reach $80 billion by 2026, reflecting a strong demand. As technology advances, the variety of PCB boards continues to expand. Each type serves distinct applications from consumer electronics to aerospace.

Expert engineer Dr. Emily Chen emphasizes, “Knowledge of various PCB boards can make or break product performance.” With ten distinct PCB board types on the market, each has unique features. Some offer durability while others prioritize flexibility. This diversity can be overwhelming, highlighting the importance of informed choices.

The rise of smart devices and electric vehicles is shifting industry standards. However, many businesses still overlook the significance of selecting the right PCB board. This can lead to costly mistakes and inefficiencies in production. Companies must stay updated on trends and innovations. This awareness is key to thriving in a competitive landscape.

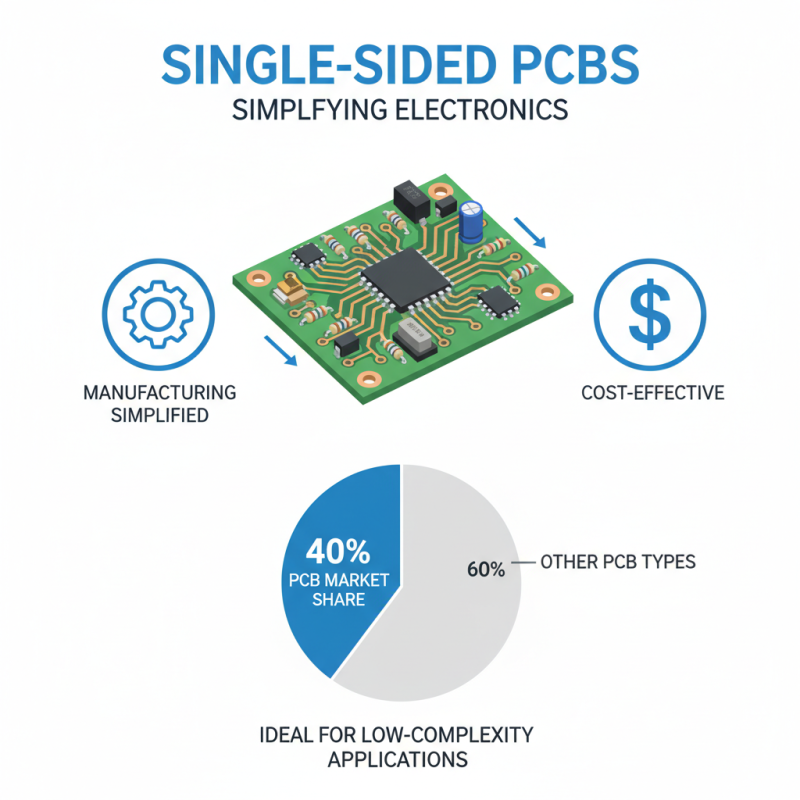

When discussing PCB boards, it’s essential to understand the various types available. The most common type is the single-sided PCB. These boards have conductive pathways on one side and are ideal for simple electronic devices. According to industry reports, single-sided PCBs account for approximately 40% of all PCB production. Their simplicity makes them cost-effective for mass production.

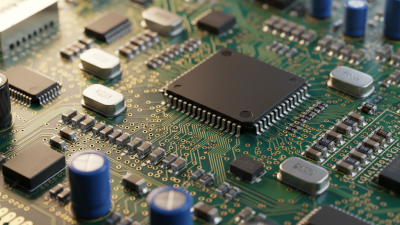

Double-sided PCBs are another prevalent type, featuring conductive pathways on both sides. This design allows for more complex circuits. They are widely used in applications ranging from consumer electronics to industrial machines. However, while double-sided PCBs offer versatility, their manufacturing process can be challenging. Data suggests that their production requires precise alignment, increasing the risk of defects.

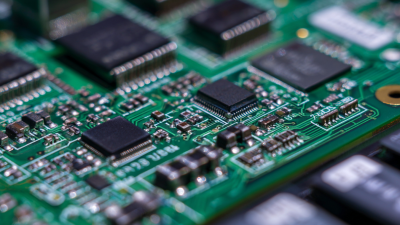

Multilayer PCBs, which can consist of three or more layers, provide even greater complexity. These boards enable more compact designs and higher circuit density. Yet, they can be expensive and cumbersome to manufacture. Some designs may unintentionally introduce issues, making testing crucial. This complexity can lead to manufacturing errors, which could impact the final product's quality, spotlighting the industry's ongoing challenges.

Single-sided PCBs, also known as single-layer PCBs, are a crucial component in electronic products. They have conductive pathways on one side and components soldered on the same surface. This design simplifies manufacturing and is cost-effective. Industry reports suggest that single-sided PCBs account for approximately 40% of the PCB market share, indicating their prevalence in low-complexity applications.

These boards are commonly used in consumer products, such as calculators and toys. Their straightforward design works well for devices with limited circuits. However, the simplicity does come with limitations. For instance, complex devices may require more layers, which single-sided boards cannot provide. This compromises their use in advanced applications, like smartphones.

While single-sided PCBs are reliable, they can be challenging for modern electronics. Engineers must carefully design around their restrictions. In some cases, designers have to rethink their approach when a single-sided PCB fails to meet performance needs. This reflects a necessary balance between cost, efficiency, and capability. It’s crucial for engineers to acknowledge these challenges while developing new technologies.

Double-sided PCBs are increasingly popular in electronic design. These boards have conductive material on both sides. This feature allows for more complex circuit designs. Traces can be routed in multiple ways, optimizing space and performance.

One key benefit is their compactness. Designers can pack more components into a smaller area. This is essential for devices like smartphones and wearables. However, the increased complexity can lead to challenges in manufacturing. These boards may require more precise alignment during assembly, raising the risk of errors.

Their use cases span various industries. In automotive systems, double-sided PCBs help manage numerous signals efficiently. Similarly, in consumer electronics, they provide durability and functionality. But it’s important to assess the design’s requirements. Sometimes, simpler PCBs may be sufficient, leading to cost savings. Attention to detail in the design process can make a significant difference.

Multilayer PCBs are essential for modern electronics. They consist of multiple conductive layers separated by insulating material. This structure allows for more complex circuits in a compact space. According to industry reports, the multilayer PCB market is expected to grow by over 20% by 2025. This is driven by advancements in technology and demand for miniaturized electronics.

Designing multilayer PCBs can be complex. Each layer must be carefully planned for signal integrity and power distribution. Engineers often face challenges in thermal management. The density of components increases heat generation. Reports indicate that improper heat dissipation can reduce component lifespan by up to 50%. Designers must be meticulous in layer stacking to balance performance and reliability.

Mistakes in multilayer PCB design can lead to costly errors. A common issue is inadequate space between layers, causing shorts. Layer misalignment can result in failed manufacturing processes. It's crucial to conduct thorough simulations and testing. The complexity of multilayer designs often requires experienced engineers to mitigate risks effectively. Despite the challenges, the advantages of multilayer PCBs cannot be overlooked.

Flexible and rigid-flex PCBs are transforming circuit design. These innovations allow for tighter spaces and complex layouts. According to a recent industry report, the global market for flexible PCBs is expected to reach $60 billion by 2027, growing at a CAGR of 10.5%. This growth reflects the increasing demand for compact and lightweight electronics.

Flexible PCBs can bend without breaking. They fit into unusual shapes, which is crucial for advanced devices. Rigid-flex PCBs merge the best of both worlds. They offer solid support where needed, while allowing flexibility. This makes them ideal for applications in smartphones, wearables, and medical devices. However, these designs can be challenging. They require precise manufacturing and careful material selection. Any lapse can lead to failures, affecting device performance.

When considering these PCBs, cost is often a concern. The expense of production can deter some manufacturers. They must weigh performance against budget constraints. Additionally, repairs and modifications can be complex. This means careful planning is essential from the outset. Reflecting on these challenges reveals that while flexible and rigid-flex technologies hold great promise, their implementation demands rigorous attention to detail.

| PCB Type | Description | Thickness | Flexibility | Common Applications |

|---|---|---|---|---|

| Rigid PCB | Traditional circuit boards that are stiff and non-flexible. | 0.2mm to 3.2mm | No | Consumer electronics, automotive systems. |

| Flexible PCB | Circuit boards that can bend and flex, allowing for more compact designs. | Less than 0.2mm | Yes | Wearable devices, medical equipment. |

| Rigid-Flex PCB | Combination of rigid and flexible boards, providing versatility and space-saving. | 0.2mm to 2mm for rigid; less than 0.2mm for flex | Yes | Smartphones, tablets, and compact electronic devices. |

| Multilayer PCB | Consists of multiple layers of conductive material, offering high density. | Varies based on layers | No | Complex electronic devices, computers. |

| Double-Sided PCB | Has conductive paths on both sides, allowing for denser circuits. | 1.0mm to 2.0mm | No | Power supplies, amplifiers. |

| Single-Sided PCB | Simple boards with components on one side only. | 0.8mm to 3.2mm | No | Basic electronic devices and home appliances. |

| High-Frequency PCB | Designed to handle high-frequency signals without signal loss. | Varies | No | Aerospace, telecommunications. |

| Aluminum PCB | Metal-based boards that provide excellent heat dissipation. | 1.5mm to 3.5mm | No | LED lighting, power supplies. |

| Ceramic PCB | Made from ceramic materials, ideal for high-temperature applications. | Varies | No | Telecommunications, automotive sensors. |

| High-Density Interconnector (HDI) PCB | Employs microvias for high-density circuits, offering compact design. | Varies | No | Smartphones, tablets, and laptops. |